|

04/02/24

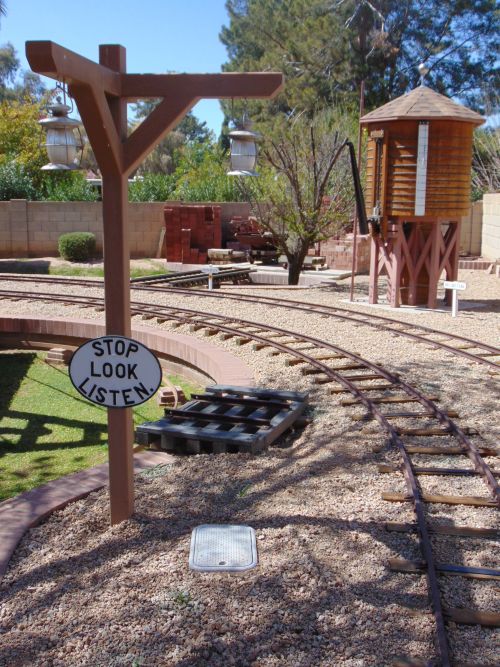

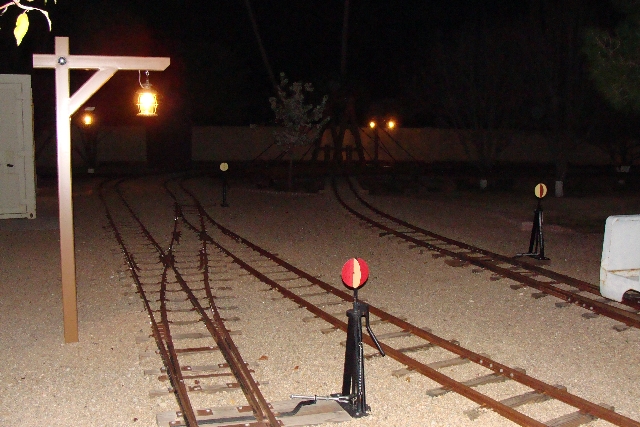

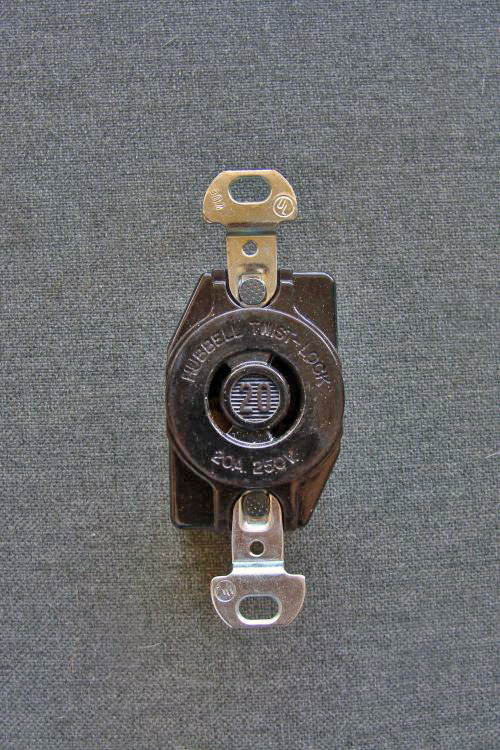

We have had issues with our trackside railroad lights for a year or so. They worked great for the first several years after they were installed. Each of our five poles has at least one light fixture, on and off switch and a power receptacle. The light circuit is on one breaker and the receptacles are always hot and on another breaker. All the wiring is in conduit and each pole has its own underground box.

|

Several months ago we started having intermittent issues with the GFCI receptacle on the last pole. I would reset the GFCI and it would be fine for an hour a few days or a few weeks and trip again. I would reset. After a bit it wouldn’t allow me to reset. We replaced the receptacle with no change. We uncovered and looked in the boxes. The gaskets had deteriorated a bit over the years so we replaced them. There was some moisture in the last two boxes on the line, but it wasn’t clear if it was condensation or a conduit leak. We thought we had isolated the issue to something in one of those two boxes or in between the two boxes. We replaced a couple of wires nuts and cleaned some connections and everything started working fine. A few days later both of the breakers started shutting off.

|

We aren’t electricians. After several more hours of trying to figure it out we left those two breakers off and handled other projects. I had a professional electrician out here this month working on something else for me and mentioned this issue. I ran the issue history by him. He was quiet for a few seconds and said matter of factly that he believed the problem was in the last pole the one that was initially tripping the GFCI. He said he had a postponement on a project and he could come out the following week and look at it if I was interested. I said I was and to schedule that. Dave and I located and dug out all of the underground boxes for him.

|

He arrived the following week and within a couple hours had determined that the issue was in the conduit sweep going from the box up into the last pole. He surmised that it is the low point of the conduit and that any moisture was collecting in the sweep and degrading the wires in there to the point that sometime there was an intermittent short. He bypassed the sweep and everything was fine and no shorts. He then went ahead and rewired it bypassing that sweep permanently. We went ahead and added a landscape box at each pole to cover and provide access to each underground junction box. It has been nice seeing those lights working the past few days.

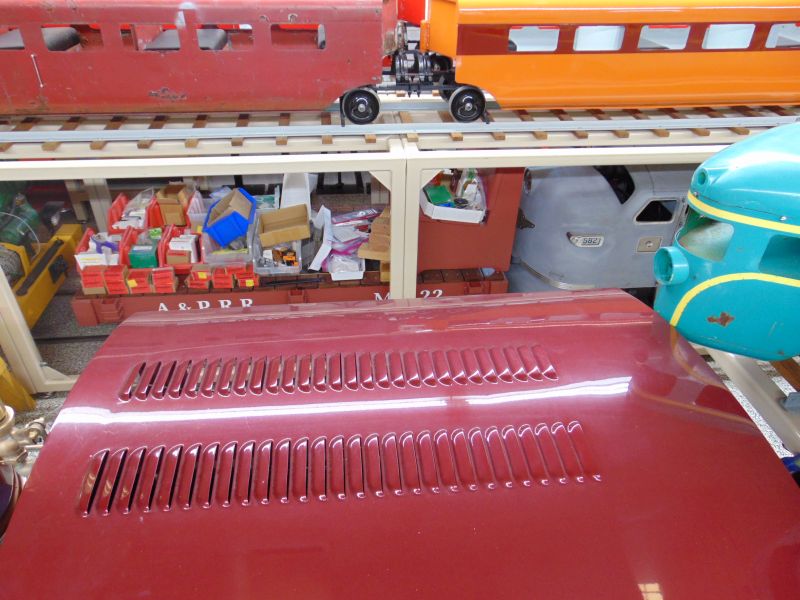

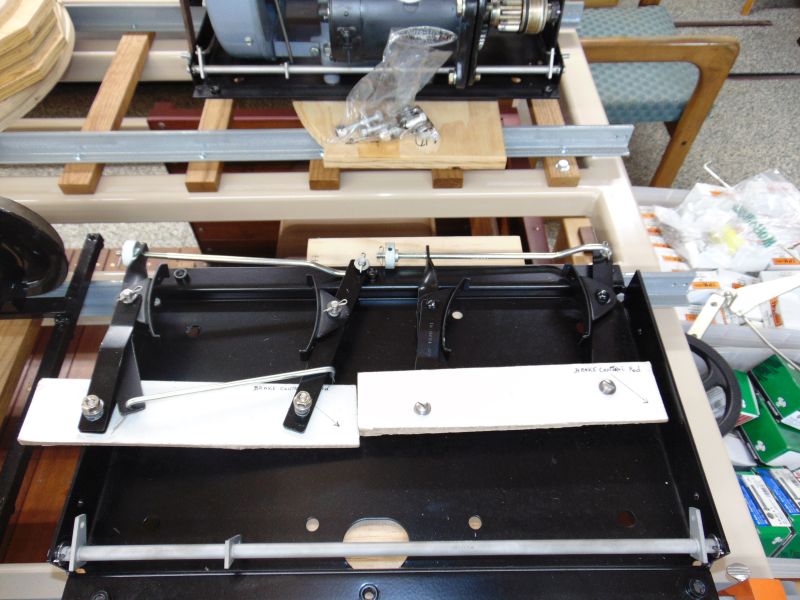

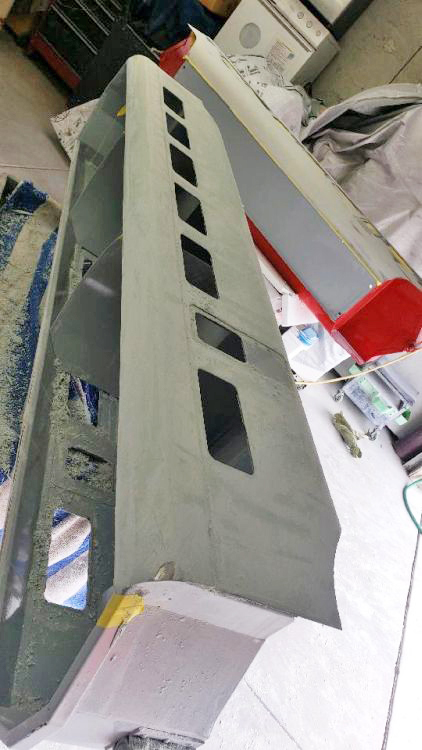

We trimmed the louver panels for the Coconino to the desired shape and size. We drilled and pre-fit them and I lightly sandblasted them to get good paint adhesion. We painted in flat black and then and painted the top of the cab for a better paint match. We also painted the screws and I got I the panels installed. We ground the points off the underside of the cab. We remounted the cab to the chassis and made some modifications to the cooling fan air deflector in the engine compartment, it should run cooler. I have been pretty busy with painting and some other projects and haven’t had much time to run her; she should see lots of action this Fall.

|

|

|

|

We sorted through and mounted assorted trim pieces to the trains on display in the engine house as we continue our evaluation of what trim fits and matches other trim pieces. I have been collecting bits and pieces of trim for these trains for 30 years from many different sources and there is some inconsistency.

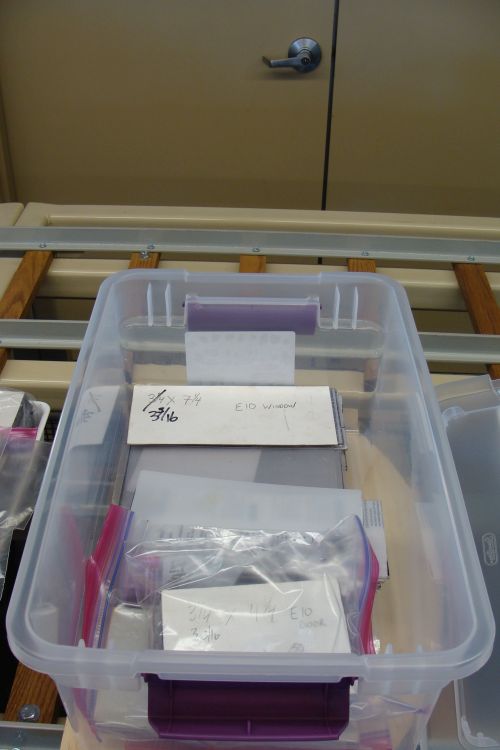

We mounted a handful of Pullman windows in the postwar G12 observation car. The Pullman windows were an expensive option and most buyers opted for the Plexiglas windows. We mounted a few of those in one of our late model E10 coaches, but the Plexiglas is so clear that you can’t tell the windows are even there. I am considering a light car tint over the Plexiglas for a better look. We also acquired a couple of more trim pieces this month.

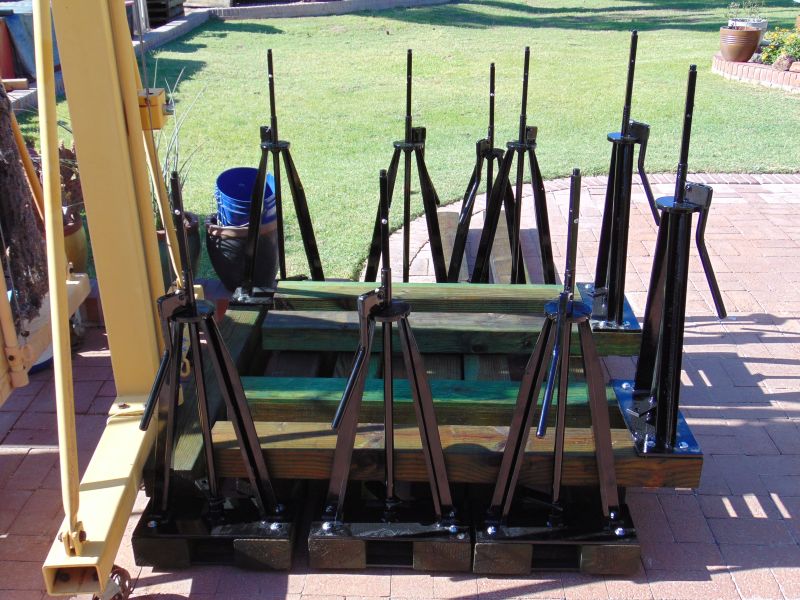

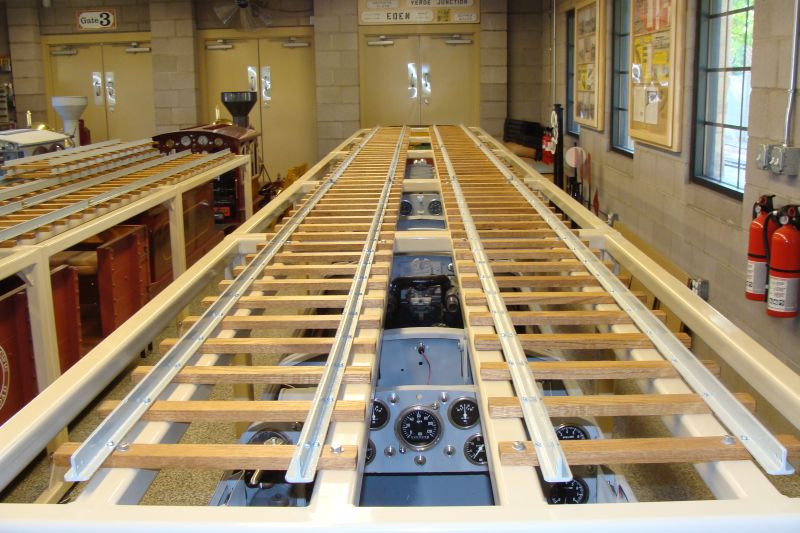

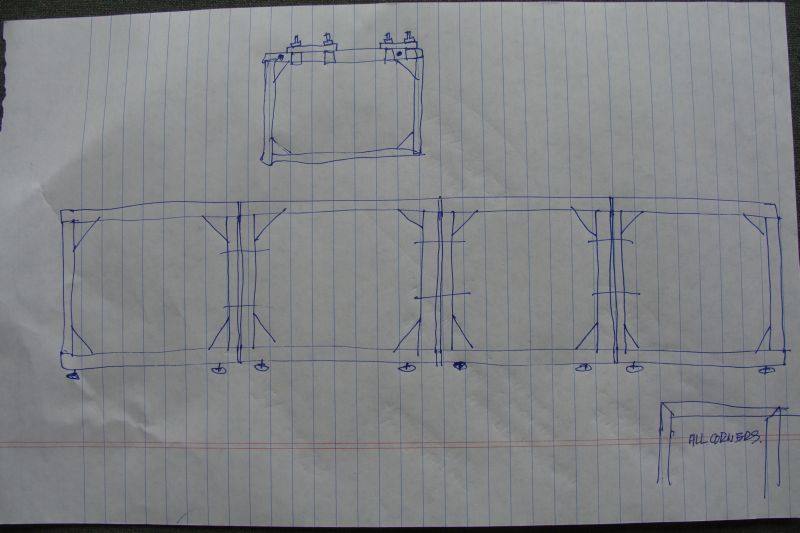

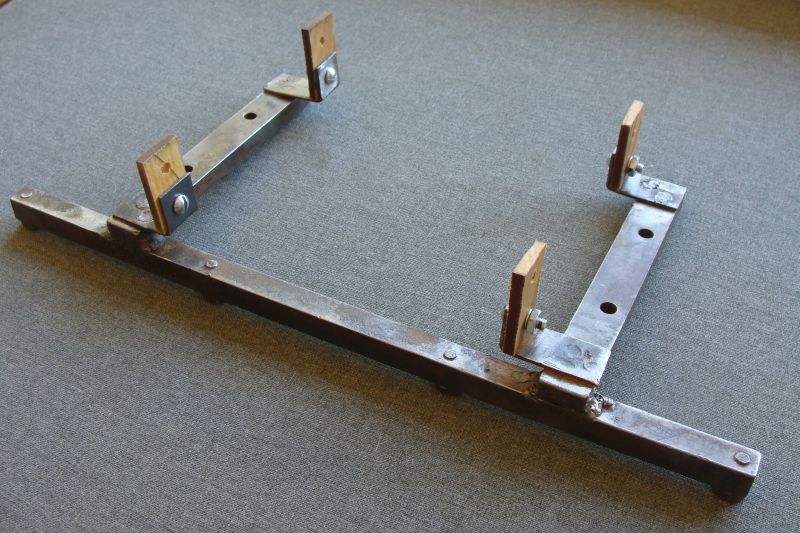

Work has begun on the displays I designed to display various MTC wheels in the engine house. The metal parts need fabricated and then the wood panels will be added.

We are also building the prototype for our steaming bays racks. Hopefully we will assemble the first one this fall.

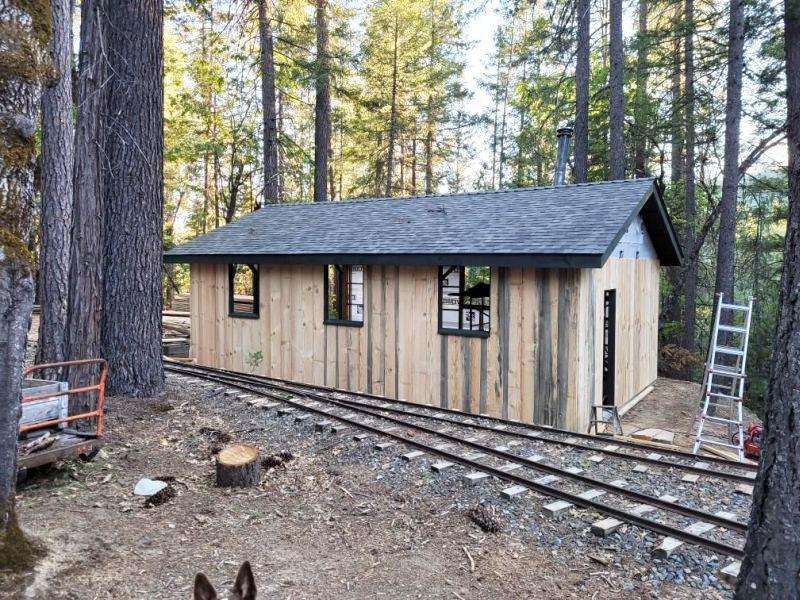

We acquired six 6 foot x 15 inch by 8 foot tall industrial shelving units. We will have another storage building on site this fall and will use the shelving units to better organize our MTC parts. More to come on this project later this spring.

We mounted the balance of the bridge and trestle numbers.

|

We painted the mounting hardware of the full size switch stand new ties.

We started the touch up on our E10 wheels. We have a bit of wire wheel work remaining and they will be ready to install.

|

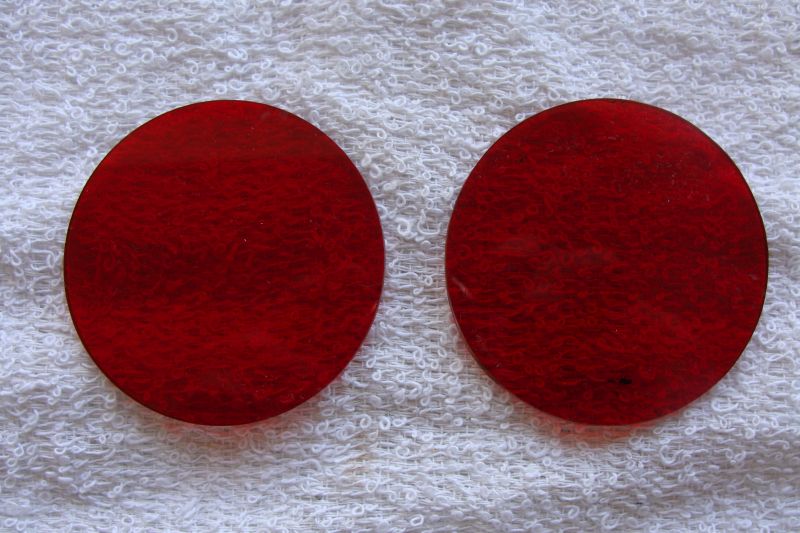

Our post-war G12 has the Pullman window shades option which was an expensive upgrade from the standard clear lexan windows that were common. They had spray paint and other substances on them that we worked several hours on to clean up. I hope to get them to the buffing and polishing vendor in April. They won’t look new, but will look pretty good.

We finally received our replacement 48v 20 amp smart charger from Big Battery; it only took four months to replace the brand new defective one they had shipped previously. We got it mounted; it is unclear yet whether it works. Do not under any circumstances buy a “smart” charger for lithium ion batteries; buy a regular old fashioned charger instead. The “smart” chargers are less than worthless.

We got some additional work completed on the second level of the engine house, but progress was delayed many times because of several multi-day rain storms. I was finally able to match the brown paint of the upper trim work. The upper story was thoroughly sanded, had two coats of primer applied where it was sanded and the caulking has been completed. The yellow areas received two coats of paint as did the brown trim. The additional trim that we are adding should be completed and installed in early April. Some touch up remains as well as painting the vents. I am pushing to have this painting project completed by the end of April as it starts getting very hot up on the shingled roofs here after that.

|

|

|

|

|

Happy and safe railroading everybody!

01/28/24

We started on freshening up the upper exterior of the engine house this month. We re-nailed the panels and galvanized flashing into place, caulked some of the seams and cracks and started filling the checking with epoxy filler. There is still a great deal of caulking, sanding, priming and painting remaining. I am adding an additional horizontal trim piece to each side above the flashing and hope to start the painting in April and have it completed before the heat arrives in May. It will look very nice again once we get her finished in a few months.

|

|

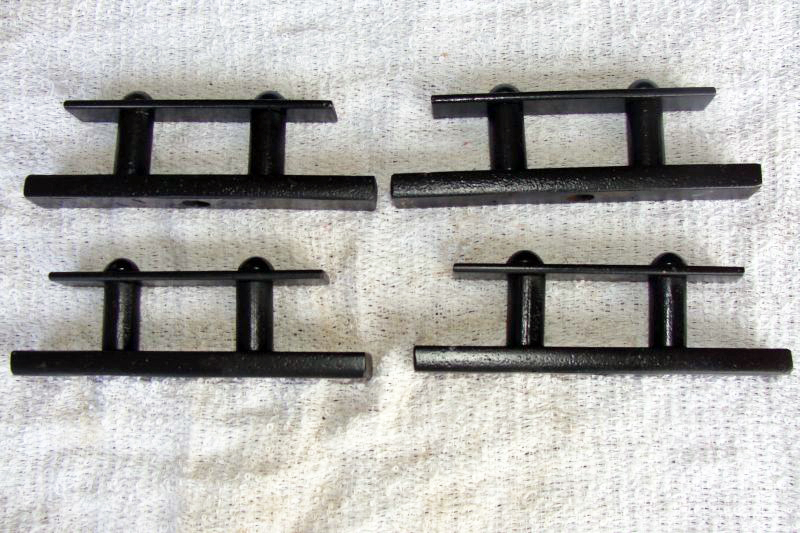

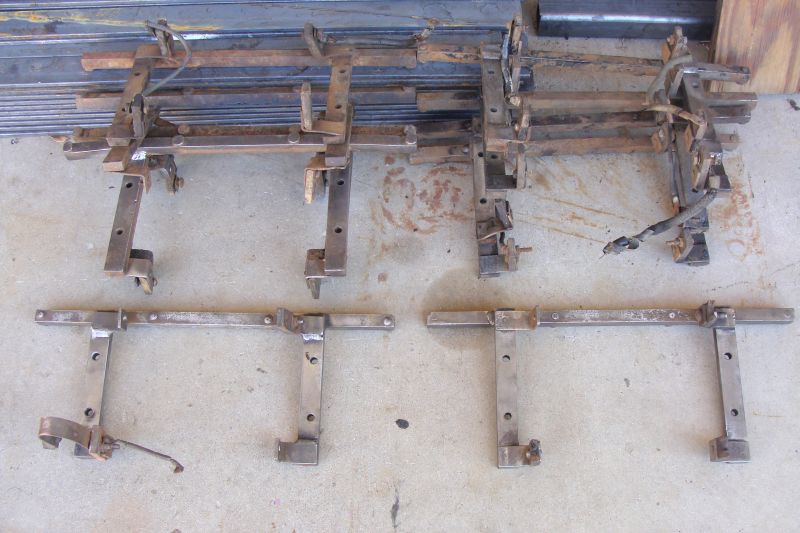

We have a collection of 12 full size switch stands most of which are different varieties from different railroads. Many are very top heavy and to eliminate the fear of one toppling over and hitting someone, all were mounted on wood 4 x4s for many years. Every few years, termites, ants and dry rot would get the best of the 4x4s and they were replaced with new ones to restart that cycle. I recently replaced the wood 4x4s with new steel ones. We boxed each end, had them powder coated and added rubber feet to keep them up off the ground. The first 4 switches had their 4 x 4s replaced in November. Seven more had their 4 x 4s fabricated in December. We’ll install them in January.

|

|

|

We started the process to add number plates to the second side of each of our five trestle signs. Originally, I had planned on only having the numbers on one side of the sign posts, but we operate in both directions and I realized it would be nice to have the numbers on both sides. We acquired and drilled the mounting holes in 10 additional 3 inch diameter by ¼ inch thick round discs. I had them powder coated in mustard yellow to match the originals and we will number them in January again using masks created by Darrin and Jana Weddle of Miracle Railroad Products. The extra fours discs will eventually be used to identify four future steaming bays that we hope to construct.

We continue our efforts to control the overheating issue with the Coconino. In that regard, we were able to source two rows of 20 3 inch louvers. We will be modifying the cab top to add the louvers and also will be redesigning the existing cab fan and deflector cooling system for the Wisconsin motor in January.

We added number plates to our 10 switch stands on the A & P. They turned out pretty well. Our switch no. 1 is where our first bridge originally stood and was the first track that we laid on the railroad the numbering follows the mainline in counter clockwise fashion and once the mainline loop is completed the sidetrack switches are numbered again in counter clockwise fashion. The number plates are mounted to the switch stand base and easily viewed when lining the switch. On our 16 gauge harp switch stand, the number plate is just below the flag.

|

|

My now 1.5 year old puppy, Annie has chewed the corners off of the bench seats on 6 of my 7 picnic tables; this is an ongoing issue. Splicing and other repairs beyond making the seats a few inches shorter again wasn’t an option. A race track in the East Valley closed down recently and I was fortunate enough to acquire several of the aluminum planks used for seating and footboards through Facebook Marketplace at a very reasonable number. We shortened the aluminum planks from 8 ½ feet to 6 feet and reapplied the end panels. We got them installed this month on the six tables. The installation hardware is really slick and easy and none of the hardware shows. The mounting brackets are adaptable to virtually any existing hole spacing that needs matched.

|

|

|

|

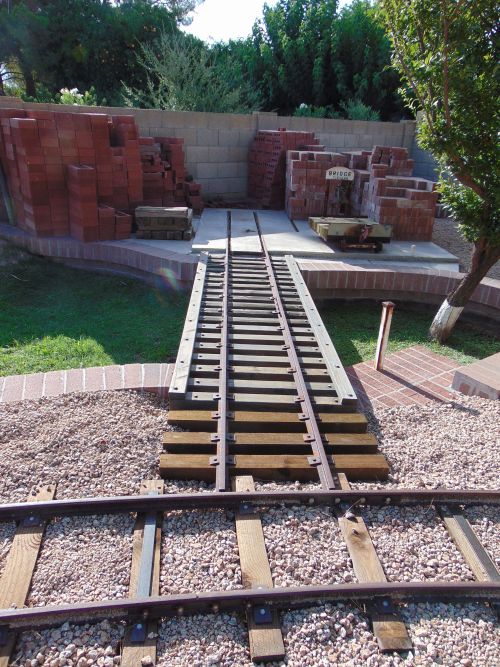

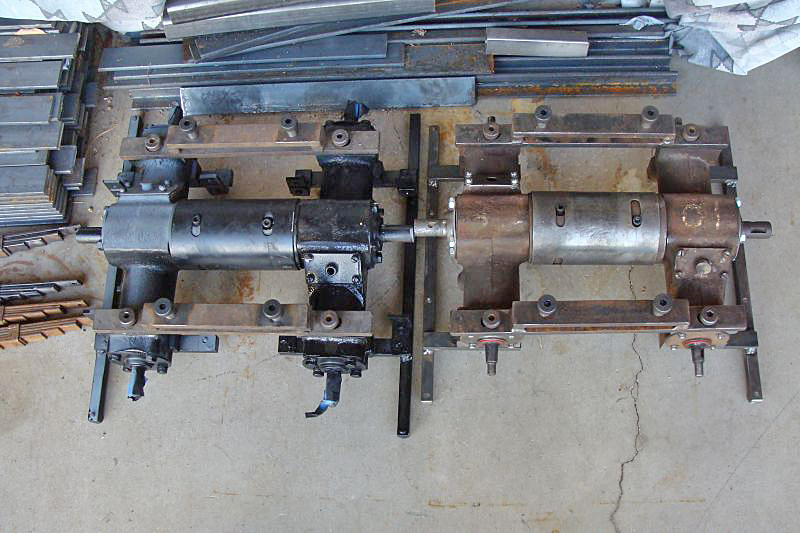

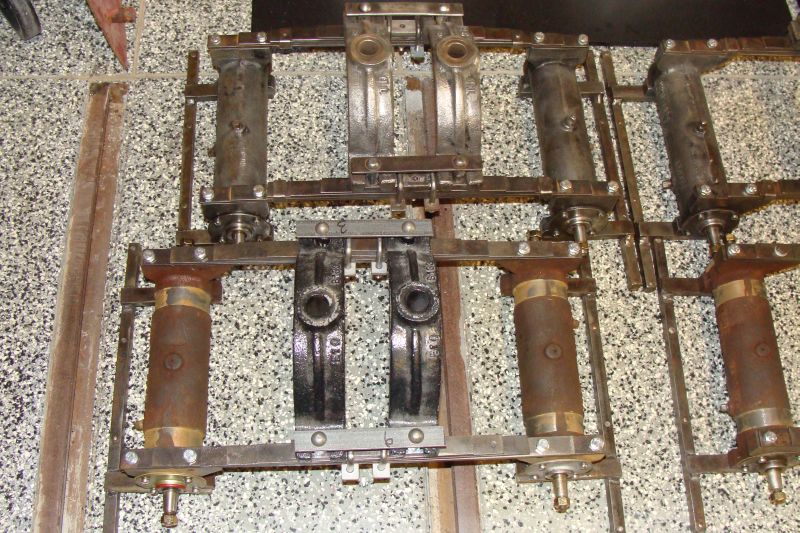

We continued working on our three E10 switches and put in a couple of long days on this project. We are starting the fine tuning on two of them (one left and one right) and welding some track feet holes closed and drilling some others so that the ties will line up straight. They have been a great deal more work than I originally thought they would be, but I am still very happy to have them. Two of them await their final adjustments and the third still has a way to go – 25 man hours or so remain on the third one.

We also have acquired two G12 switches. Initially, I thought they were also a matched set of left and right, but it turns out that they are both left hand. They are on the East Coast. I am still working on the most economical way to get them to Arizona. Anyone have a right hand switch they would be interesting in parting with?

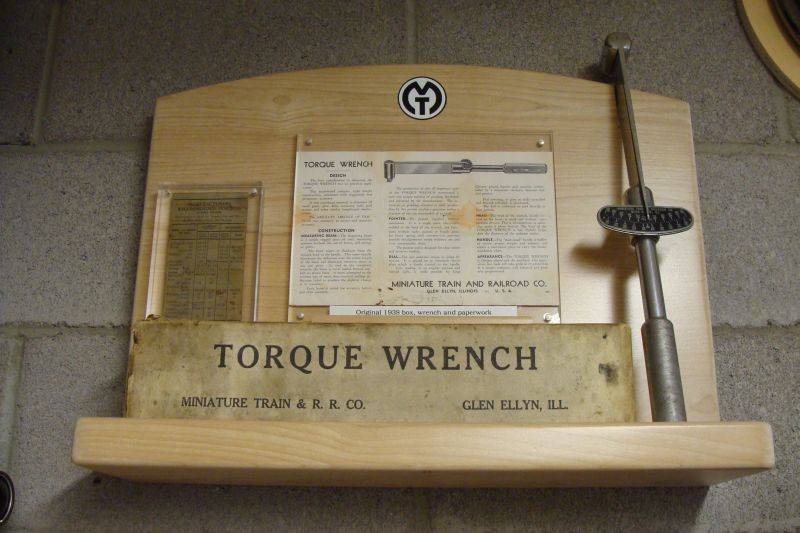

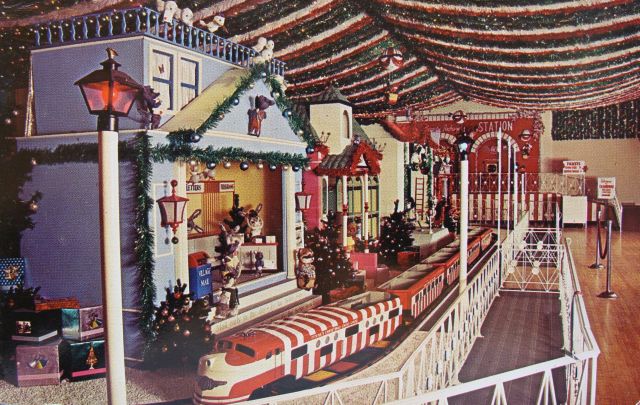

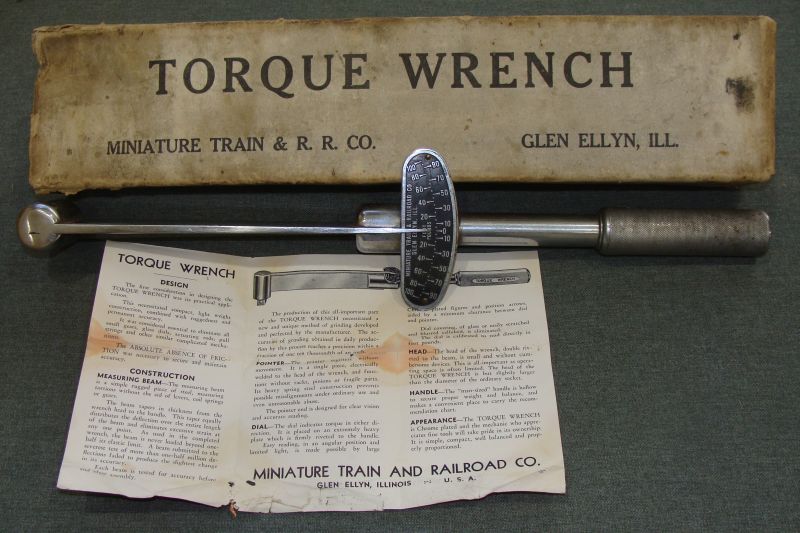

Dave acquired 2 more E10 postcards for our MTC collection and an Ottoway “Pump it” car from 1957 that we can now display alongside our Hodges Handcars. I acquired a couple of Sturtevant torque wrenches labeled “Lab” that I suspect came out of one of the several Sturtevant facilities in Addison, but I don’t have the provenance to prove that yet. They are cool pieces nonetheless.

|

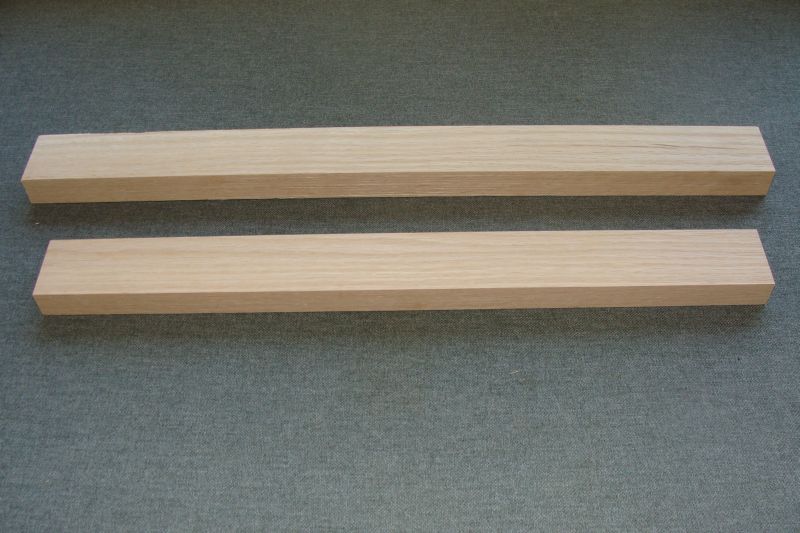

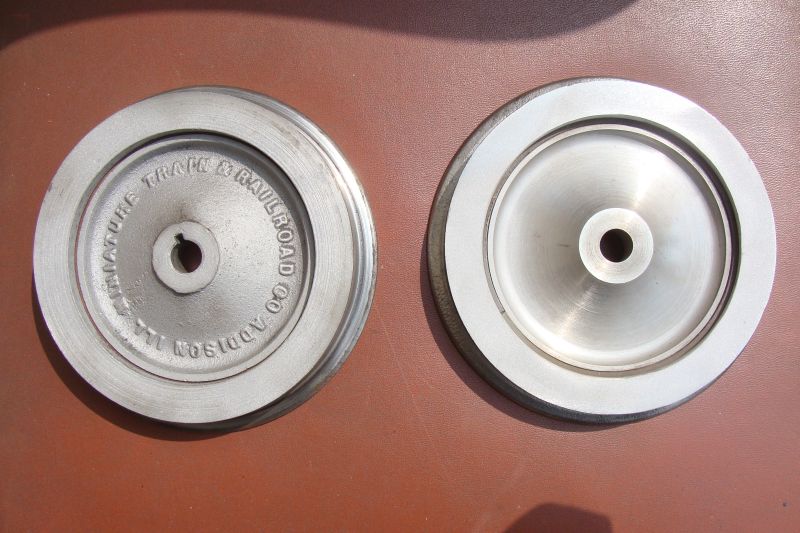

I completed my first pass at designing a display for our MTC wheels for the engine house. I am hoping to display twelve wheels. Once completed, the display will include one of the first G16 wheels ever cast, a G14, G15 and G16 wheel from Rensselaer and a G16 wheel from the Miniature Train Division of Allan Herschell in North Tonawanda, New York. Others will include two E10 wheels, one from Glen Ellyn and one from Addison and two G12 wheels one with the Miniature Train and Railroad Company casting and one with the later Miniature Train Company casting. There will be a couple of spaces for future acquisitions. The displays, as currently envisioned, are a combination of steel and whitewashed Alder. This will be revised a couple of times before it heads into production, it will probably be fabricated and mounted over the summer.

Happy and safe railroading AND Happy New Year everybody!

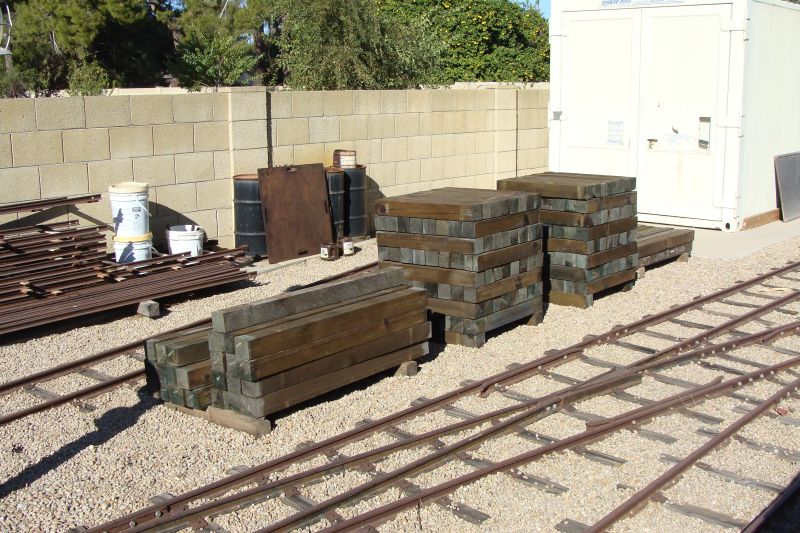

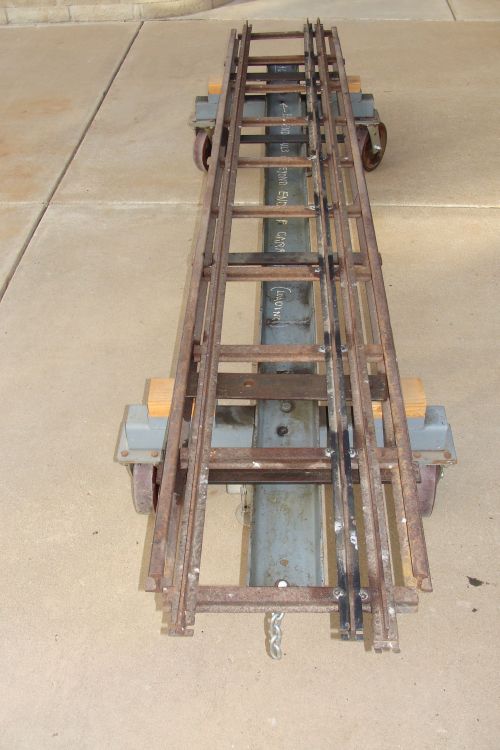

In one of our relatively recent E10 acquisitions, we acquired quite a bit of E10 rail and parts of 3 E10 switches. One switch (left hand) was about 80% complete, one right hand was about 50% complete and a second left hand was about 25% complete. We had a mix of at least one of every part, but some were right hand and some were left hand. We are going to reproduce the parts needed to have a functional right and a left hand switch and may end up doing the same with the third switch. I have been collecting MTC products and equipment for thirty years and own 5 E10s, but these are the first E10 switches I have ever seen. G12 switches pop up from time to time, but not E10 switches. I’m very thankful that we had the opportunity to acquire these and restore them to operating condition.

|

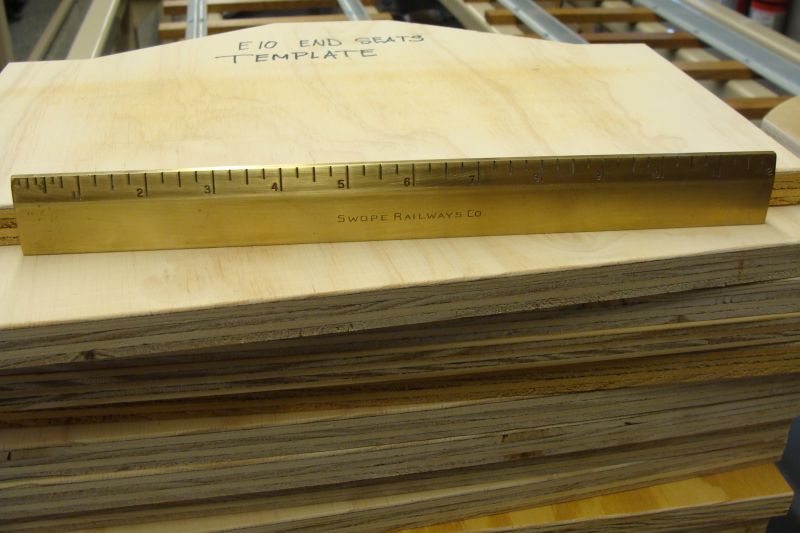

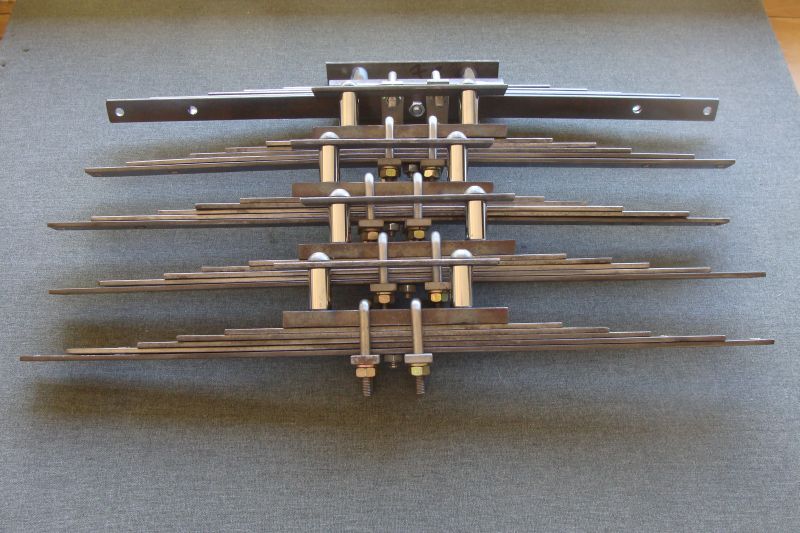

We got a good start on the process this month and have made considerable progress on having the first two switches rebuilt. We didn’t have the frogs for any of the three E10 switches; I had several photographs of MTC G12 frogs and we used the same design scaled to E10 size. We also fabricated the frog wings using the one E10 one that we had as a pattern. The geometry involved and getting all the parts fabricated is more complicated than you would think. Like the E10 track panels that we restored previously, we will use oak ties with our E10 switches. I’m still uncertain about whether I will have them powder coated and how they will be displayed.

|

|

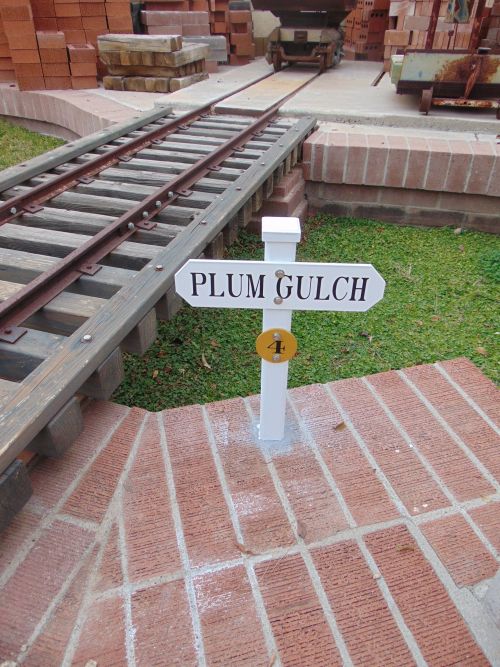

We cleaned, primed and painted our Plum Gulch sign post and added the cap, sign and trestle number. All of our signs are completed except for a depot sign on the back of the engine house.

|

|

We have a collection of 12 full size switch stands most of which are different varieties from different railroads. Many are very top heavy and to eliminate the fear of one toppling over and hitting someone, all were mounted on wood 4x4s to make them more stable. Every few years, termites, ants and dry rot would get the best of the 4x4s. I replaced the wood 4x4s with new steel ones. We boxed each end, had them powder coated and added rubber feet to keep them up off the ground. The first 4 switches had their 4x4s replaced this month. We have the 4x4s for 7 more switches in fabrication. We also repainted all 12 switches and cleaned all of their targets with Meguiar’s Ultimate Compound.

|

|

|

We got our milk and cream cans back in place on the baggage cart.

|

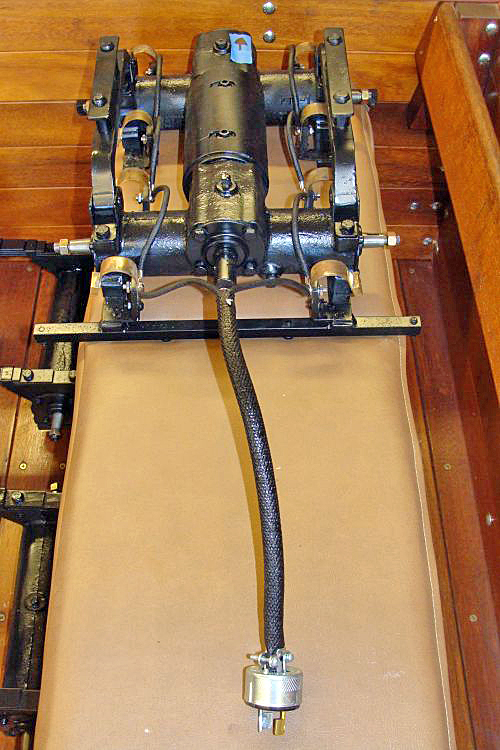

We pulled the leaking high pressure hydraulic hose on the Coconino, had one fabricated and installed the new one. I am glad to report no leaks.

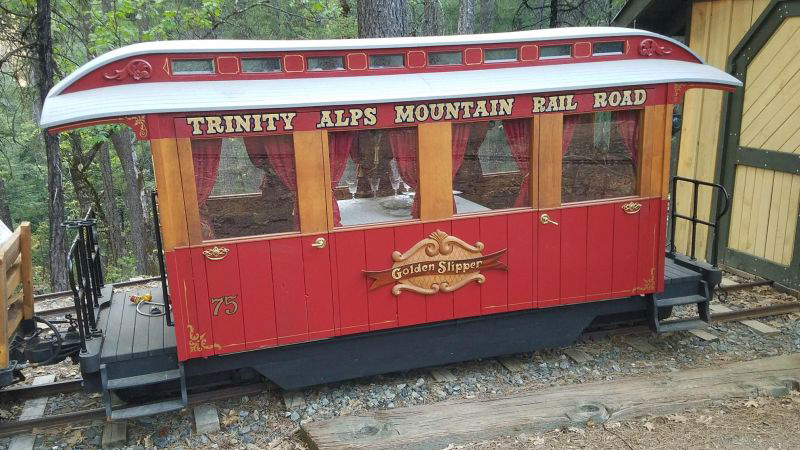

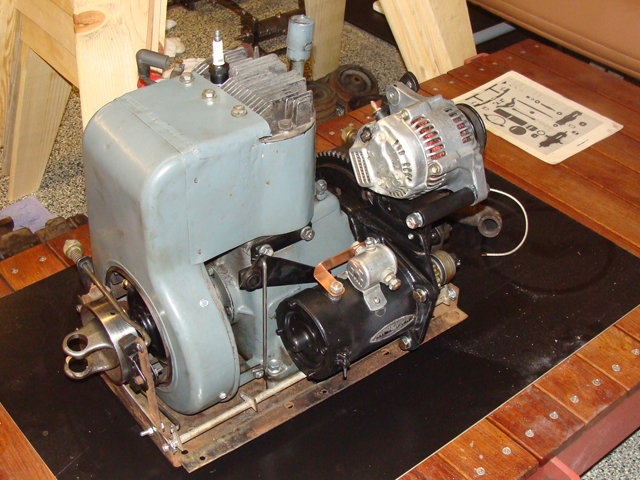

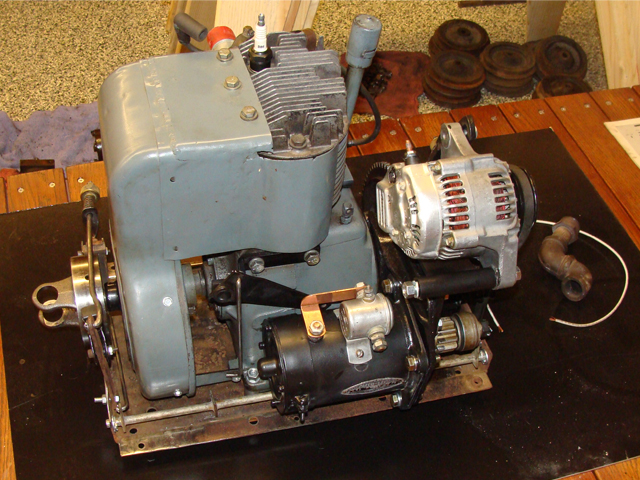

When our friend Malcolm Mackey acquired the S16 named Coconino many years ago, it was missing many parts and was a years long project. The cab top of the cab was badly damaged, but the sides were in reasonably good shape. He fabricated a new cab roof and reused the side panels. His new roof did not have the two rows of 28 4 inch louvers for help with dissipating the heat. We continue our efforts to control the overheating issue with the Coconino. In that regard, we were able to source two rows of 20 3 inch louvers. We will be modifying the cab top to add the louvers and will also be redesigning the existing cab fan and deflector cooling system for the Wisconsin motor.

|

|

|

We bead blasted, polished and painted our 21 additional E10 wheels. We’ll start installing them on the trucks next month.

We started the process to add number plates to the second side of each of our trestle signs. Originally, I had planned on only having the numbers on one side of the sign posts but we operate in both directions and I realized it would be nice to have the numbers on both sides.

We finished sanding, priming and painting our two Adirondack style chairs made from wine barrel staves. I was looking for a Jimmy Buffet/Kenny Chesney vibe with my paint job and I think I accomplished that. Next up for seating refurbishment after the first of the year are the two park style benches on the north side of the engine house.

|

|

We got started on freshening the upper exterior of the engine house this month. We are re-nailing the panels, sanding, caulking, priming, painting and adding an additional trim piece to each side. It will look very nice once we get her finished in late April or early May.

|

We acquired another MTC torque wrench, another piece of G12 tooling and a couple of MTC catalogs for our museum this month.

We are still working on matching our years’ long collection of trim pieces with our 4 E10s and 2 G12s that are stored in the engine house. We have an additional E10 that is not stored in there and several additional E10 and G12 cars. Most are still in need of fresh paint, but the bling is dressing up the equipment in the engine house for certain.

|

Our new lithium Ion batteries in the Sandusky have been a learning experience. We made the upgrade from the conventional lead acid batteries in late spring of last year just before it got hot here. Shortly after that conversion, we shut down actually running the trains for the summer. It turns out that if the batteries don’t see any activity for 30 days their internal electronics place them in “dormant” mode. The smart battery charger that was recommended and I purchased with the batteries will not get the batteries out of the “dormant” mode. I had to buy a second non-smart charger to accomplish that function. I am still somewhere in the middle of the learning curve, but I do like the performance of the batteries once you know how to maintain them.

Other projects coming soon – repainting the support structure and base of our water tank, new wood and paint on our freight depot shipping scale, building some prototypes for a steaming bay or two off of the turntable and some displays racks for MTC wheels in the engine house.

We have a new vendor for our A & P shirts and should have the first batch of them on site in February.

Happy and safe railroading AND Merry Christmas everybody!

11/29/23

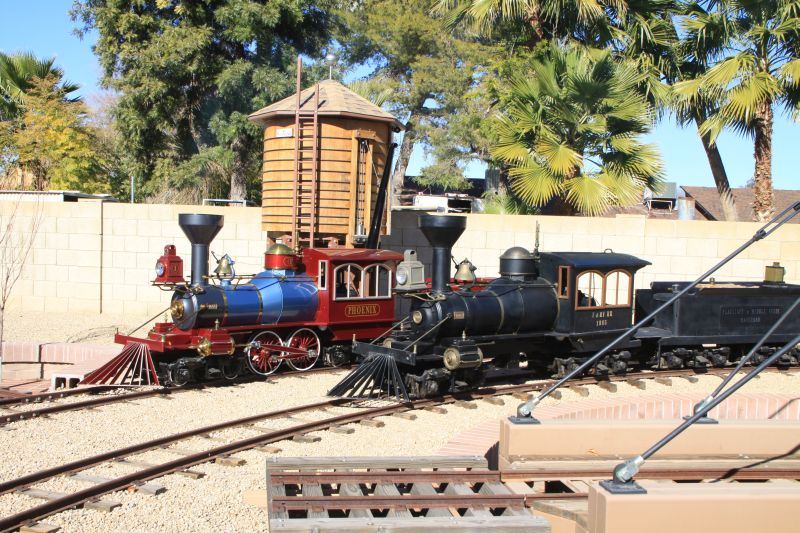

Jim McDilda of Redding, CA, who is restoring G16 no. 720, visited the Arizona and Pacific Railroad this month. We talked Bud Hurlbut, MTC, trestles, turntables, transfer tables, engine houses, wheel flanges, ballast, door opening dimensions and more topics than I can recall at the moment. It was a great visit.

Jim is donating tooling for G12 port holes to the A & P for inclusion in our MTC museum. We very much appreciate his kind donation of MTC items. Our long time friend Rick Nairn has made multiple donations over the years to our little MTC museum. Malcolm Mackey supported our activities in many ways over the years and a couple of anonymous folks have donated as well. All donations are greatly appreciated as we strive to collect, restore and preserve MTC and Allan Herschell products and equipment that were a big part of so many lives.

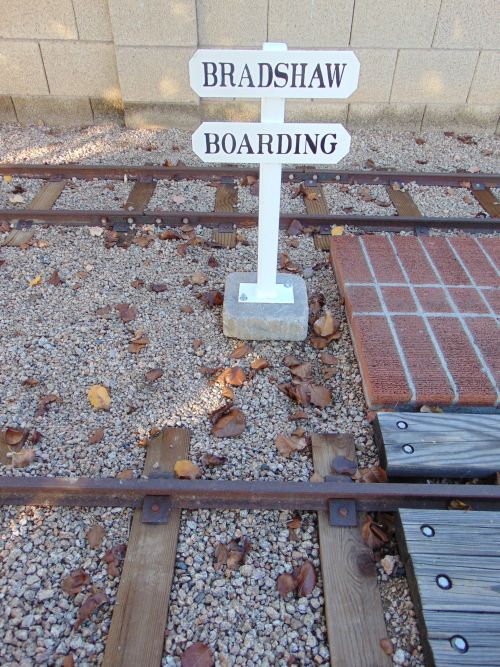

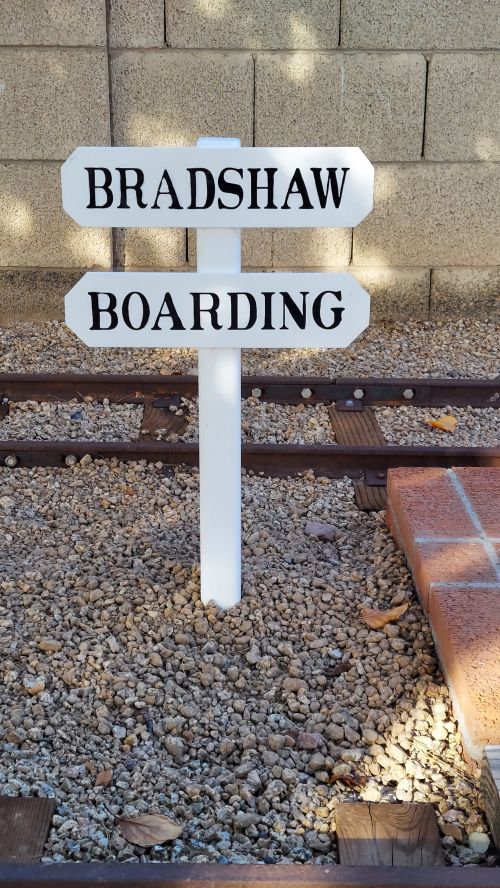

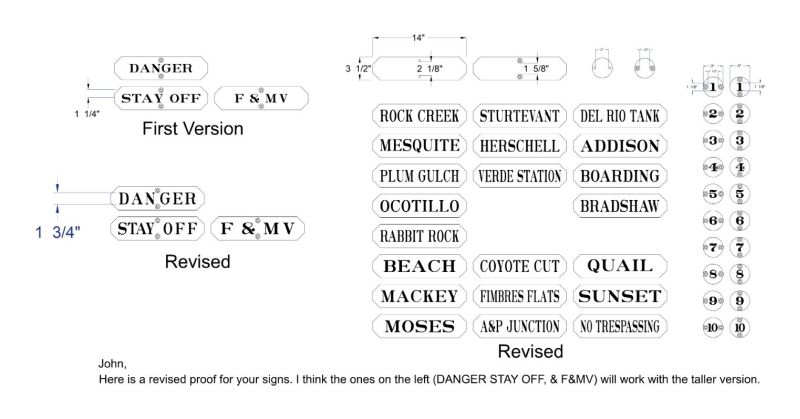

We spent a great deal of time this month working on our track side signs. Darrin Weddle of Miracle Railroad Products did a great job with our masks. Even with detailed masks, it is still a lot of work turning them into finished signs. The signs and sign posts are welded steel and power coated in flat white. The lettering is gloss black. The numbers indicating the trestle numbers are gloss black on mustard yellow powder coat. Next month, each switch stand will receive a white on red number denoting the number of that switch.

|

The six trestle signs were the first ones mounted and Rock Creek was the initial effort. We utilized stainless steel hardware to tie the upper and lower mounting plates in place. We have a total of 3 front yard signs on 3 posts and 31 signs on 16 posts in the backyard now in place. These signs have been a long time coming. We have been thinking and talking about signage for years. The trestles all had numbers and some were referred to by name, but the spurs, sidings and locations were hit and miss and some had a couple of different names over the years. We finally clarified and have formalized those names. Some of the names relate to early Arizona railroad locations such as Del Rio Tank and the Bradshaw Boarding area, others to historic figures in the park train world Sturtevant and Herschell named for Paul Alan Sturtevant and Allan Herschell. Some others are named for men that I respect tremendously that worked for MTC and later Herschell, George Moses and Bob Beach. Malcolm Mackey got me into this hobby and encouraged my efforts in many ways. Rabbit Rock was a location on the F & MV, Quail is a location at which many baby quail appear every spring from under the tarps that protect our MTC coaches from the elements. And the list goes on.

|

|

|

|

|

|

|

|

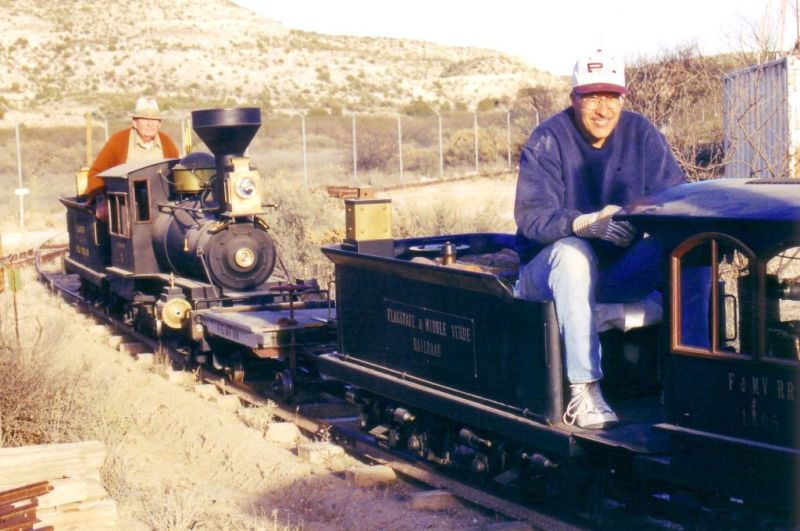

I was involved with Malcolm Mackey in restoring/replacing his wood signs on the F & MV over the years. Mother Nature was and is unrelenting in the Verde Valley of Arizona too. Malcolm’s overall railroad theme was of a narrow gauge Colorado Railroad (Rio Grande Southern) struggling to make it through the years of the great depression. He sought a weathered look and worked hard to make new materials look worn and distressed. At times, Mother Nature’s effects on his signs shortened their life cycle beyond what we had hoped. I have a few of the salvageable signs from the Flagstaff and Middle Verde Railroad on display in our engine house. Some are first generation and some second generation.

|

I elected to use powder coated steel for our signs on the A & P. In time, Mother Nature will win here too and the lettering will fade and need refreshed, but I am hoping to extend their lifecycle by a few years. As a homage to Malcolm and his Flagstaff and Middle Verde Railroad (the rolling stock and power units of which reside at the A & P) our signs are in the RGS lettering style.

|

|

We completed our latest restoration of our baggage cart in October. We scraped, primed, caulked and painted the entire cart including the spoked wheels. We replaced two large support brackets that were repaired at some point with some very amateurish welding, stained and replaced the wood and replaced 90% of the hardware. The old girl looks pretty good for being roughly 100 years old.

|

|

We received most of our long awaited window springs and hood grilles for our post war G12 and late E10 last month. We will install them next month just to confirm the fit and finish and dress up the equipment on display in the engine house. We also received additional E10/G12 truck arches from the machine shop and I got them into and back from the powder coater mid-month. We also received 6 sets of E10 throttle and brake handles that I commissioned through our machine shop. Three sets mount with a set screw and three others are threaded into place. We have a couple of each on our current E10s.

|

|

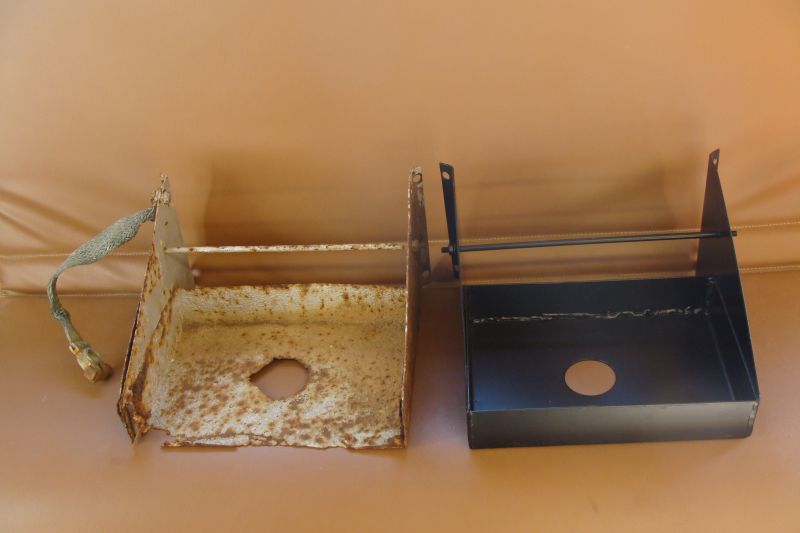

I received news this month that our two reproduction G12 gas tanks are being produced and will likely be delivered before the end of the year. The fabrication of these tanks has been bumped numerous times as time-based projects for larger clients have been placed. I’m excited that these tanks are now in production.

We replaced the ignition switch on the Coconino with one designed for use with a magneto. We had her on the rails briefly before a hydraulic line failed and was spraying hydraulic fluid everywhere. I hope to get the hose removed, a new hose built and get it replaced in November.

We hosted several friends this month that visited the museum and got rides behind the Sandusky. Some were local and others from Colorado Springs. Everyone seemed to have fun and we may have a couple of junior engineers in the making.

|

|

Happy and safe railroading everybody!

11/28/23

We started working on our post-war G12 ob car no. 168 – we removed 2 sheared off bolts in the top casting, repaired and reinstalled the ob end reinforcement panel and did a couple hours of preliminary bodywork around the ob end fender wells. It looks like a forklift or some other piece of equipment was used to lift this car at some point and it damaged the wheel wells, tore up the reinforcement panel and pretty much destroyed the rear seat. The “repair job” was poorly executed and may have been as irresponsible as the original damage. The vertical face of the rear seat on the Ob end was punctured and pretty mangled. The patch was welded in place by a beginner and not even centered. The top of the same seat had pinholes and was sagging in the middle. We cut the seat out and replaced the metal panels. We needed to use two panels instead of one. The front seam will be filled and finished by our body and paint man, we just rough things in and have the professionals finish it up. We replaced the four damaged grab irons with ones in nice shape. She was wiped clean and moved into the engine house with our other equipment waiting to go to paint and body.

|

|

|

We finished much of the painting the baggage cart and there will be some touch up. There is lots of square footage and many nooks and crannies. It has been very hot here so painting was completed a couple hours here and a couple hours there. The wood planks arrived and we ripped then to width, cut them to length stained them a very light gray and got the holes all drilled. We still have a bit of trim finish work remaining before she is completed.

|

|

|

|

We installed our E10 rack stands. The stands are a Jerry Graves design. They allow us to display a third E10 car on rack no. 3. The curves in the stands closely match those of the E10 wheel wells. We used truck arches to tie the new design in with the original MTC design.

Grab irons were cut, fit and mounted on our CA orange and yellow E10 observation car and our late version E10 coach, loco no. 20 and loco no. 24. The post-war G12s were much more consistent in size and location of the grab irons than the E10s, especially the pre-war ones. Grab irons were cut, fit and installed on our post war G12 ob car. They still need cut, fit and installed on two post war G12 coaches, two CA E10 loco coaches and E10 no. 45. We also test fit and temporarily mounted the original handles on the early version G12. They are very different than the post-war versions. They will soon go out for polishing and re-chroming.

|

We mounted the MTC breast plate logo on our post war G12 loco and also added its four grab irons and the headlamp bezel and lens.

|

We have the faux horns mounted on each of the five engines that are currently in the engine house. I have another set ready to go on E10 no. 45 when we start on her restoration.

|

I have been collecting the trim pieces for our E10s, G12s and G16s for many years, but as I have continued buying equipment the lists of parts missing and parts acquired are constantly changing. Keeping the lists updated is a job by itself. Hole spacing and the trim parts themselves changed slightly over the years of manufacture and means parts aren’t always interchangeable. It reminds me of that old Johnny cash song “One piece at a time”. When the parts are made over a twenty year period, they may not fit. I think his lyric said something about an “adapt kit”. Getting the parts tailored for and mounted on specific equipment is helpful in knowing what I have and will fit on which cars and what is still needed. We still have dozens of trim pieces and hundreds of window pieces to install. Seeing the old girls with all their trim is exciting for Dave and me. Yes, it will all come off before the equipment heads to paint and body, but will be tagged, bagged and labeled for its specific train, car and side and will be remounted upon its return.

We repaired the sheet metal damage to our E10 transition coach which has the smaller windows matching those of the G12 and utilizes the post war G12 window frames. We also riveted the truck pins to the car body.

|

We only received one of the two original cab side ladders for our pre-war Addison G12 when we found her. Our friend Russ Robinson, duplicated that ladder for the other side and he did a great job as it’s beautiful and an exact reproduction.

We repaired the whistle on the Coconino. Some moisture has caused the mechanism to be frozen in the open position releasing all the air before it actually entered the whistle. Everything is functioning again as designed.

The masks for our trackside signs arrived last month and we got started on them this month. We have a long way to go before they are trackside signs…

It is still hot here, but we had the Phoenix and the Coconino out and about the rails briefly stretching their legs. We are looking forward to cooler weather soon.

Happy and safe railroading everybody!

10/12/23

I approved the proofs for our first group of sign masks that Darrin Weddle and his team at Miracle Railroad Products in McAlester, OK have been working on. They should arrive in mid-September. I am looking forward to the next phase of that project which will get underway in late September or early October.

|

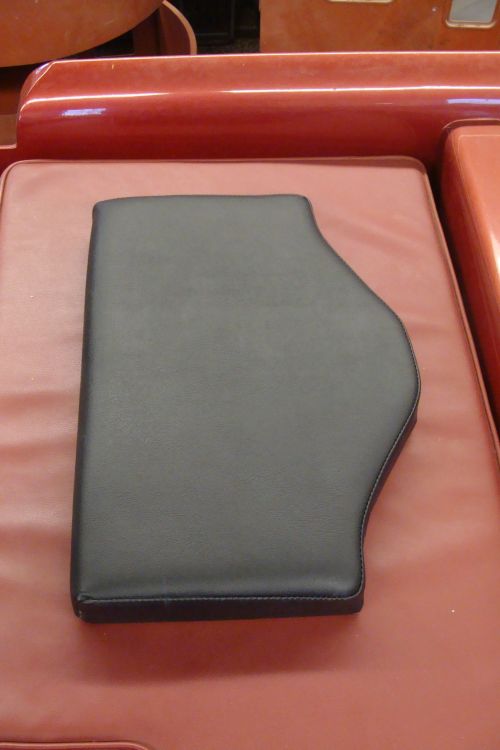

My neighbors, George and Tinker Fimbres, finished and delivered our next 10 E10 and G12 seats and, as always, they look great.

Our 16 E10 wheel tires were delivered this week and we matched them with an insulating ring and hub and got them pressed together. We have 21 wheels completed that just need a bit of bead blasting and paint work to complete them and have them ready for installation. We have a few extra wheel and axle parts just in case we take on another E10 project some day.

|

We built our prototype stands for atop our second E10 rack in the engine house. After testing them, we needed to make a design change and made those modifications and sent them back to the water jet vendor. The modified design is going to work well.

|

We have a depot baggage cart at the A & P that Dave and I got started on repainting the metal components and replacing the wood bed this month. We are replacing the hardware for the second time and there is a lot of hardware. The new hardware is on site and the wood will be ordered shortly.

|

|

|

We had this old cart before we had the A & P. It’s an interesting story how she came to be here. I started work at a large insurance company in 1980. At the time I was writing articles about Arizona railroading and had two book length manuscripts I was writing about early Arizona railroads. One of the guys working a few desks from me at the insurance carrier approached me one day (circa 1981) and said I hear you’re a railroad guy. I responded that I hadn’t worked for the railroad, but was a huge fan. He said I might have something you would like to have.

He and his wife had just bought a house that for many years had been owned by a longtime railroad family. As the story went, the prior owner retired after 50 years in depot work with the railroad and it gifted him a baggage cart. It sat in the backyard for many years. He passed and then his wife and the house went up for sale. He showed me photos of this baggage cart sitting in the corner of the back yard. Only a few pieces of wood remained, one axle was badly bent, a wheel was damaged and the metal end of the tow handle was missing. My co-worker’s wife wanted a rose garden where it was sitting. He said if I removed it I could have it. The catch was I had to remove a couple of sections of wood fence panels to remove the cart and then replace them without any damage to the panels and it needed to be gone within two weeks or it was going to the scrap dealer. I said I was all in.

I enlisted my brother Dave, a high school student at the time, and a couple of our friends, one of whom owned a long bed Ford pickup, and the next Saturday we were off. I had no idea how heavy it was lol. We removed the fence panels carefully and without major difficulty. The baggage cart had been there a long time and the wheels had sunk in the dirt over the course of many rainy seasons and we had difficulty getting them free. The bad wheel and axle created difficulties rolling it and the end of the handle was missing so pulling and steering it was an adventure. We persevered and finally got it out of the backyard and into the alley behind the fence. It was much heavier than anticipated and lifting it high enough to get the first end and then the second end into the truck bed of a high riding truck was not an easy task. It was too long to fit in the bed and the rear set of wheels sat precariously near the far edge of the open tailgate. We didn’t have any professional tie down straps, just some rope and tied it down the best we could. We carefully replaced the fence panels and we were off across town.

All was great until we got to an overpass where the road went up and over the railroad tracks. As we started up the overpass the weight of the cart pulling and stretching the ropes while Dave and I were holding onto the cart trying to keep it in the back of the truck almost had the cart and both of us laying in the street. Just as it was about to get really ugly we crested the overpass and all the weight shifted the other way and helped us get the rear wheels fully back onto the tailgate. We were crazy lucky we didn’t kiss the asphalt and maybe get run over in the process…

I was still living in an apartment and didn’t even have a place to put it. My dad allowed me to temporarily put it in his garage. Dunbar Spring and Steel straightened the wheel and axle for me, my dad made an axle cap out of epoxy resin, an old college roommate with access to a blacksmith shop and crew had a repro of the original metal handle made and Dave, dad, friends and I cleaned up and painted the metal frame and chassis and replaced the wood based on old photographs. We have had her roughly 42 years and this is the 4th time that we have repainted her and replaced the wood. She has had several more coats of paint than that. The upper portions have had various shades of green over her years. The undercarriage was originally red with several coats of green over that. We scraped, wire brushed, caulked, sealed and primed the inside of the baggage cart frame where moisture collects and got started on the painting. We aren’t sure of her exact age. The very early ones had wood spoke wheels, then came all metal spoke wheels and then this version with hard rubber wrapping the metal spoke wheel. I have been told 1900 - 1920. She has been at the A & P since the beginning and feels like part of the family. We anticipate having her painted and fully reassembled late in September or early October.

|

|

|

|

|

|

We installed the faux horns on E10 no. 26. We also installed the drumhead, the rear driveline cover and the throttle and direction handles.

|

Happy and safe railroading everybody!

08/11/23

We moved our post-war G12 into the engine house this month and she will stay inside until she heads to body and paint. It is interesting seeing her sit next to the pre-war Addison version and noting all of the similarities and differences.

|

|

We received 12 of our 24 upholstered seats back from George and Tinker Fimbres late in June and they look great. As a result of a shipping mistake by one of their vendors providing seat fabric for a 1963 Chevy Nova that they are working on, our second group of 12 more seats was completed early and delivered in July. They are also working on a combination of 6 more E10 seats of various shapes and 4 more G12 seats of 2 different shapes and they should be finished in August. Once these are completed, they will have completed 99 E10 and G12 seats for us.

|

We started working on the Coconino. We replaced the battery, the fuel filter and the electric fuel pump. We also rebuilt the carburetor. For those of you that don’t know the history of the Coconino, she is no. 59-1866 and was the second S16 built. She started her life in an amusement park in Rye, New York. Our late friend Malcolm Mackey acquired her in 1991 and spent several years chasing parts to get her back together and running. She didn’t have her original Wisconsin VF4 engine (or any engine at all) when Malcolm Acquired her. Malcolm had two VF4 engines that each had issues and he delivered them to one of the two Wisconsin engine franchises in Phoenix and tasked them with building one good motor out of the two. The new motor was never right. The owner of the second Wisconsin franchise in Phoenix, Jerry Graves, was brought in as a consultant and determined the distributor rotor was incorrect for the reconstructed motor. That change solved the rough running issues, but the motor would overheat after running about 15 minutes in the Verde Valley at the Flagstaff and Middle Verde Railroad. Fast forward several years and the Coconino became part of the A & P stable of S16s.

|

|

|

|

She still regularly overheated after a few minutes of use in Peoria. We re-plumbed the hydraulics, replaced the hydraulic motors and re-geared the locomotive with no improvement to the overheating issue. A couple of years later, I burned up cylinder 4 when I overheated the engine. Cylinder 4 is the farthest from the cooling fan on the VF4 and usually the first one to incur damage. I had it rebuilt with cylinder heads from another VF4. The overheating problem was unchanged. A cooling fan was added and the exhaust was examined for a blockage and cleaned with no change.

This month we removed the distributor and coil and replaced it with a magneto and an ignition switch for use with a magneto. We have had 35 days of 110+ here and everything air cooled overheats at 110+. It may be mid-October before I know if we have the issue resolved. If the issue isn't resolved, the cam shaft may not be the right one for our Wisconsin. Hopefully, the magneto solves the problem as replacing the cam shaft is an expensive proposition.

We have 4 complete E10 trains and the power unit from a fifth. We have nos. 20, 24, 26, 45 and likely 48 or 49. We have 2 complete G12s (a very early Addison and a post-war 1947 model) and the coaches and an observation car from a third G12. We just need a third locomotive to have a third train.

We finished rebuilding our third and fourth gates and I think they look pretty good. Repainting the gate frames will be a next spring project.

|

|

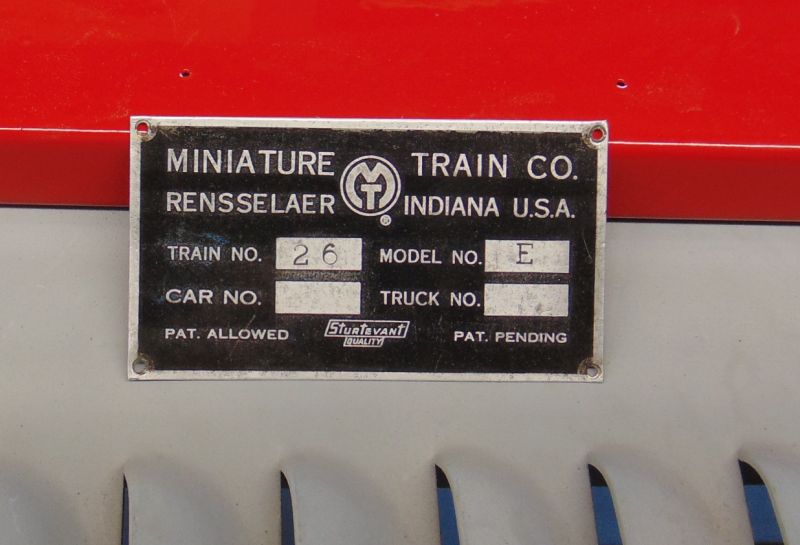

We got a few more things done on E10 no. 26. We will soon remount our number plate to that instrument panel. It is the original plate, we just touched it up and clear coated it. The instrument panel needs wet sanded and clear coated again. The horns will be installed next month. The hood will be a fall/spring project.

|

We got our A & P logo plates reattached to our turntable. It has been a while and I missed having them on there. Thank you to Amanda Clack for getting the ball rolling on that project.

|

Jerry Graves designed the prototype for our new E10 display stands. We are having some 3/16 plate water jet cut and utilizing two of our reproduction E10 arches. Using these stands instead of trucks on the outside ends of the end cars allows a third E10 car to be displayed on the no. 3 engine house rack which is twenty feet long. We should have them back early in August. As with many prototypes, they may need some modification, we’ll see.

We got a great deal more work completed on our CA E10 locomotive including getting the two hoods properly radiused and fitting correctly. We rebuilt and mounted the two hood latches and mounting brackets and mounted the hood release rods. We filled several non-original holes in the instrument panel and straightened a bend and twist in the panel. We welded closed and re-drilled a dash mounting bracket that ran as we tried to drill out a sheared off bolt a couple of weeks ago. We primed and remounted the instrument panel. We also fabricated an electrical panel cover that was missing when we acquired her; we used the panel on no. 45 as a pattern. We also cut off a welded extension to the direction lever (F, N, R) and returned it to its original configuration. We moved our CA locomotive into our engine house where she will sit until she heads to body and paint.

|

|

|

We still have 2 more pieces of equipment that will move into the engine house in the next few weeks. One is a late version E10 coach and the second is a 5 seat post-war G12 observation car. It is starting to fill up in there. We will have 13 pieces of E10 equipment, 4 pieces of G12 equipment and 8 pieces of G16 and S16 equipment in there; plus the track inspection car, two speeders and the track inspection flat car. We have 4 additional pieces of E10 equipment, 6 pieces of G12 equipment, 3 S16 locomotives and tenders, 3 G16 coaches and 13 other pieces of 16 gauge equipment that will be displayed elsewhere. I think that is 61 pieces of equipment that we are keeping for certain and some additional G12 equipment that we may eventually part out or sell. We may need to add a third layer of displays soon… just kidding. We need another building and if I keep working long enough and building supplies come down a little bit, we’ll build one in a few years.

Happy and safe railroading everybody!

|

07/21/23

Scheduling has been an issue, but we finally got our painter out to touch up the red and white and orange and burgundy E10 trains. I damaged the paint on one of the cars moving it into the engine house, the locomotive paint I damaged drilling the holes for the cab horns. There were a couple of isolated clear coat runs on the orange and burgundy cars and the red and white observation car had a couple of areas with which I was unhappy. Our painter, Norm Clark, was over for several hours one day this month and worked on all six cars getting everything exactly the way I wanted them. The cars will get moved back into the engine house in a few days after the paint is good and hard.

|

|

|

We received our 12 E10 axle halves and 12 couplers from the machine shop. We received our 5 wheel hubs previously. We await completion of 15 tires and 25 more truck arches. We should have everything onsite in late July. We used two of the axles halves to complete the final axle assembly of the last truck of our California E10. We will get that truck reassembled accept for the wheels in July.

We were readying the Addison G12 observation car to head to body and paint as the Addison locomotive was set to return before the end of June and the ob car was up next. The Top and bottom cast plates both had sheared off bolts that we spent time removing – some more easily than others. We had a heck of a time getting two of the sheared bolts removed, but eventually succeeded. Update, the body shop guys that started on our Addison train are too busy with regular business and have returned it. They made some minor progress, but nothing major. It will be stored in the engine house until I can arrange to have the bodywork completed and paint work done by someone else.

|

|

We got the 1986 AMT 600 of the F & MV Railroad running. We drained the old gas, rebuilt the carburetor, added a new battery and added fresh gas. A few adjustments later and she is running great.

|

|

We got the post-war G12 hoods adjusted and fitting like a glove and also installed the lower and upper bulkhead components.

|

We finished the rebuild of our third and final picnic table. Mother nature is tough here, but all seven picnic tables should be in good shape for quite awhile.

|

We still need to get the Coconino running and hope to do so in July.

|

Work continues on our CA E10. Several more sheared off bolts were removed. We worked on the two hoods which were mangled in previous alterations. We fabricated an original looking hood latch mounting bracket and reconditioned an original latch assembly. We will remove a number of restomod changes to the instrument panel. We will fabricate a new cover for the front electrical panel; we will use the one on Locomotive no. 45 as the pattern.

We had a rear driveline cover fabricated for E10 no. 45. She is a long range project, but is very similar to our CA train so we have panels to use as patterns to create all the missing panels on no. 45. I am so glad we were fortunate enough to acquire both trains.

We’ve finalized the naming of our trestles and various locations and are finally ready to move forward with our lettering. Many of our locations have been named informally for years and a couple of others needed a formal name so we all call certain places by the same names. I’ll get the masks ordered in the next couple of weeks.

We have at least ¾ plus tank of quality gas in each of our power units and the appropriate amount of Stabil mix in their tanks. I’ll make another trip up north in the fall and bring back enough quality gas to get each gas tank ¾ plus full. Most of the tanks are twelve gallons.

I was able to obtain a few more E10 leaf spring Ubolts this month and some very nice E10/G12 portholes. We don’t need them at the moment, but if another E10 becomes available you never know.

Dave and I have been measuring and completing early design drawings for three G16/S16 steaming bays that will access the turntable from the southeast. There may be a fourth bay that is G12/E10 dual gauge and set up for servicing that size equipment.

We are also designing a couple of stands that will allow an extra E10 car to be displayed in the engine house. I will provide plan photos of the steaming bays and stands as we get farther along in the design phase.

I have four gates on my property. One is a pedestrian gate, one is a RV gate and two are large rollback gates that allow trains to move between the front and back portions of the property. The weather here is unrelenting. Every four years I have been sanding, priming and repainting the wood in the gates and about every 10 years replacing the wood and starting over. This month I started replacing the wood with a colored wheat straw and recycled plastic product that they claim will retain its color and not crack in this environment for at least ten years. The RV gate and pedestrian gate are completed and I have the materials on site for the railroad gates. Dave and I need another couple of weekends to get everything cut, drilled and reassembled.

|

|

|

|

My neighbor George Fimbres and his son Tinker are working on the first of two groupings of 12 E10 seats and they will be completed early new month. We cut the ¾ inch thick plywood bases to size and the high density padding and material arrived a few days ago. Later this summer, they will complete the second grouping of 12 more seats.

|

|

Happy and safe railroading everybody.

|

06/30/23

Scheduling has been an ongoing issue, but we have a date set for onsite touch up on the red and white E10 train.

Although they are not yet on site, we have reason to believe that our 5 new E10 wheel hubs, 12 axle halves and several axle couplers have been completed and will be ready for pick up at the machine shop this week. Our 15 tires are still in process.

We are readying the Addison G12 observation car to head to body and paint as the Addison locomotive is set to return before the end of June and the ob car is up next. The Top and bottom cast plates both had sheared off bolts that we spent time removing – some were removed more easily than others.

We have the Phoenix running great. Like the others trains, we drained the gas tank and fuel lines and added fresh fuel. We also added a new battery, fuel pump and fuel filter and rebuilt the carburetor. We also worked on our transmission indicator light assembly and it is back in consistent working order.

|

We picked up a total of 24 truck arches from the powdercoater and got eighteen of them quickly installed on trucks. The first 4 went on the two E10 coach trucks that we’ve been working on the the next 14 went on G12 trucks. The truck arches are one of several parts that the E10s and G12s share in common.

We finished rebuilding the 7 brake vacuum canisters on the Tucson. It took about 3 more hours. Now she runs and stops great.

|

We have vacuum brake canisters on 5 of our 6 sixteen inch gauge trains. The other locomotive is gasoline/hydraulic and the hydraulic motors on the four locomotive axles provide the stopping ability. I hear some people complaining about the MTC vacuum brakes. I don’t really get it as they are easy to maintain and easy to adjust. The stopping ability is phenomenal and if slammed in full stop mode for an emergency, you may toss some folks over the seat in front of them. If you don’t properly maintain them or keep them properly adjusted, not surprisingly they won’t operate well…

MTC vacuum brakes are more susceptible to catastrophic failure than modern train brakes in which air pressure keeps the brakes from engaging and a catastrophic failure locks the brakes. Of course MTC trains weren’t 120 cars long and operating speeds weren’t 60 mph. I have never seen evidence of a catastrophic brake failure on a MTC train in which the brakes were maintained following the MTC service bulletins.

We also drained our old gas out of the G16 no. 582 and replaced it with new gas. We made a couple of carburetor adjustments and she ran great. Her battery had been on a trickle charger and it was in good shape.

We still need to get the Coconino and the Flagstaff and Middle Verde 1986 AMT running. The AMT was scrubbed up good and the five tires topped off with air. It should be running in late June and the Coconino likely in July.

We finished the rebuild of our second red picnic table and have the third and final table disassembled.

|

We cleaned and moved our E10 baggage car into the enginehouse where she will remain until she heads to body and paint.

|

We started cleaning up and repairing our CA E10. Several sheared off bolts were removed and we replaced several portholes that were missing. After restoration, we have several pristine portholes that will replace the ones on there now. The rear driveline cover had some awful looking brackets that were added by a prior owner that we cut off and cleaned up the mounting locations. The correct brackets will be attached in the coming weeks.

We also located the correct hood brackets and hood latchx2 in our parts department as well as four of the correct hood shoulder bolts. We hope to have the hoods assembled and mounted in July and this locomotive will also go into the engine house awaiting a trip to body and paint. The equipment in the enginehouse isn’t necessarily completed, but the grinding and welding work is done prior to relocation into the enginehouse. The cleaner assembly processes take place in there.

The donor hoods on our post-war G12 continue to receive attention. At some point in their lifespan it appears that something heavy was stored on them. The result was they were flattened somewhat and lost their original radius. The lack or original radius was an aesthetic issue, but also created a fitment issue. We explored several methodologies before Jerry Graves hit on the winning method. His technique got exactly the correct radius back into both hoods and they fit and operate smoothly in the locomotive body.

|

We were lucky enough to acquire a Lot of MTC rubber passenger car molding caps both left and right side. They are NOS and appear to be in great shape and still very supple. From the same source, we acquired a lot of misc. brake parts, spacers, axle nuts, etc. that are always good to have on our parts shelves.

We’ve finalized the naming of our trestles and various locations and are finally ready to move forward with our lettering. Many of our locations have been named informally for years and a couple of others needed a formal name so we all call certain places by the same names. I’ll get the masks ordered in the next couple of weeks.

I made it out to McCormick-Stillman Railroad Park one day mid-week this month when I needed to be in the east valley on business. It was a good crowd for a week day. I took a few photos and noticed what appeared to be another storage structure in the far end of the park. They’ve done a nice job depot-theming it. I took a few more photos and had to head to a meeting a couple of miles away.

|

|

Happy and safe railroading everyone.

05/09/23

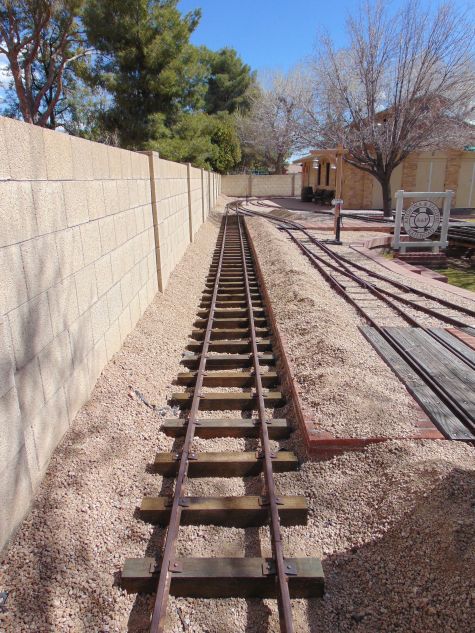

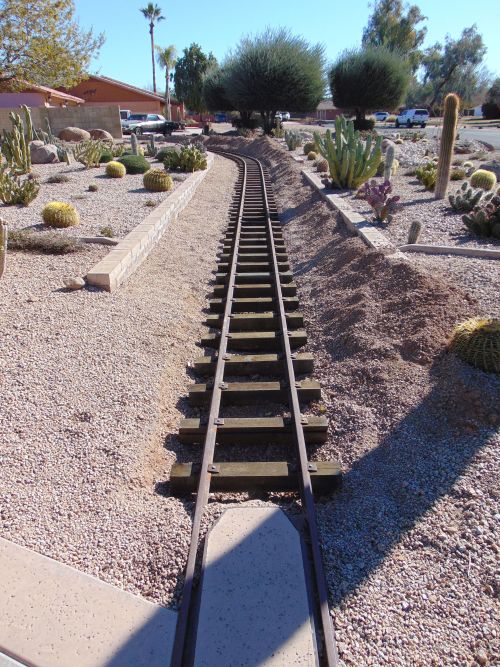

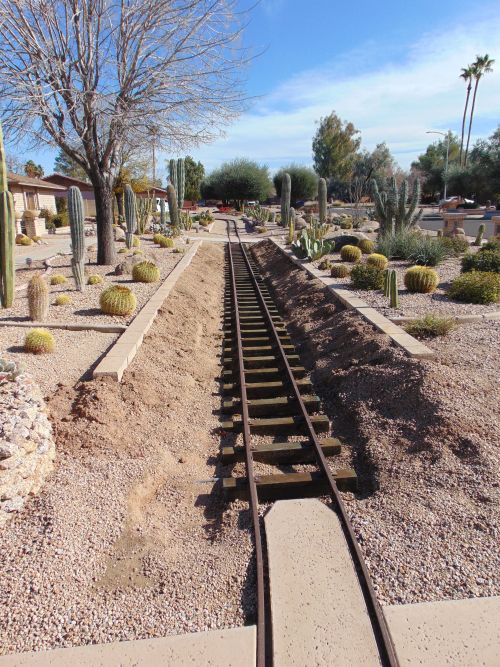

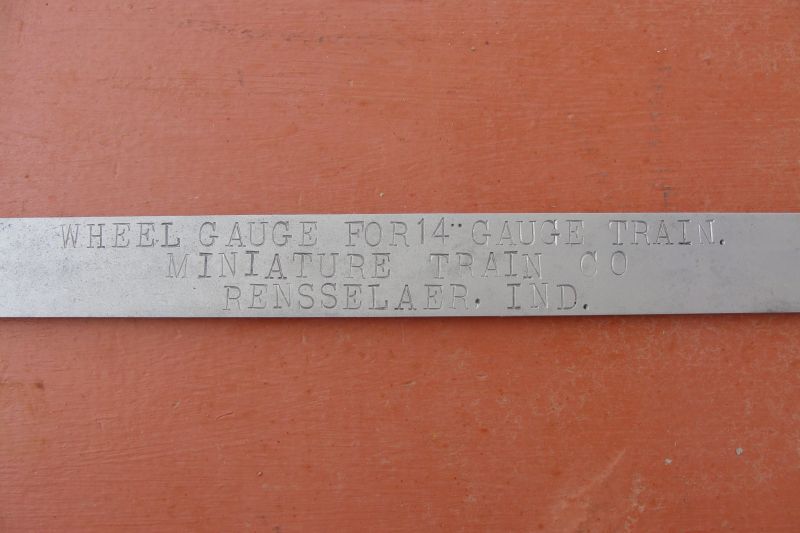

Our E10 rail from southern California arrived this month. Carlos and Vanessa Gomez delivered our E10 rail and track panels on their flatbed trailer and helped offload onto the driveway early one morning. It was great to meet Carlos in person and to see Vanessa again; they’re great folks. There are 65 complete track panels, 15 partially disassembled, but with all the components and numerous sticks of straight and curved rail. Most of the rail is in great shape and has the track connectors in place. A few will need some work, but I am so happy to have it all here. We added this track to the existing E10 track on the rack that we built for the purpose. There are a few track panels that exceed the capacity of our large rack which as a friend pointed out is a great problem to have. In the future, we will be building a similar rack to store our G12 track which is currently scattered and stored in four locations in the back yard. For those of you that are unaware, aside from the different gauge, the E10 T rail is slightly smaller that G12 rail, is insulated from the ties in the track panels and utilizes very different rail connectors.

|

|

|

As many of you know, I have been disappointed with the pace with which our E10 and G12 projects have been getting through body and paint. I have six pieces of equipment back in three years. I have engaged a second shop that believes they can deliver a coach or locomotive every forty-five to sixty days. I started them with our pre-war Addison G12 locomotive. It was picked up on April 5 and is scheduled to return to the A & P in late May. It is a blue and white paint scheme. We’ll see how they do. They are off to a good start as a prior owner had performed some awful Bondo work where the front pilot meets the nose. This body and paint group cut the pilot off the nose, ground and sanded both clean and welded the pilot back in place. It looks so much better already! If the final product meets my expectations, the Addison observation car will follow and then the post war G12 locomotive and then its observation car. The four coaches will follow. We are hopeful to have six of the eight G12s pieces of equipment completed and a couple more orange and burgundy cars painted and back here by the end of the year.

|

|

We received 20 truck arches back from the machine shop and I got them to the powder coater. They should be ready for pick up early in May. We still have forty more truck arches to go to the machine shop, but I want them to fabricate our E10 wheel hubs, axles and tires first. We received the first 5 wheel hubs back from the machine shop and are awaiting 7 more. Several E10 coach axles and tires are being fabricated and we hope to have the wheel hubs and tires on site by the end of May.

Most of our equipment was inactive for three years as a result of the passing of our mother and the need to replace our ground contact ties as they had outlasted their useful lifespan after 25 years and our efforts to replace ties here and there was generally unsuccessful. Ultimately, our track was removed for our massive tie replacement project in which all ties with ground contact were replaced. As the result of their inactivity, our five gasoline powered S16s and G16 needed the old gasoline drained, carburetors rebuilt, the fuel cleaned and new batteries purchased and installed. The goal is to have all the equipment back up and running by our October 1 fall running season. We have acquired a 55 gallon metal drum for the old fuel and its safe and responsible disposal at our next city drop off event. I also acquired a 30 gallon plastic drum and a friend of mine who lives outside Maricopa County purchased fuel without ethanol and visited twice as these trains do so much better on old style gasoline than the newer fuel mix with all of the additives.

We got the old gasoline drained out of the Phoenix, Tucson, Coconino and Red River. The fuel in our G16 no. 582 and our 1986 AMT will be drained in May. We rebuilt the carburetors of the Tucson and Red River and purchased new conventional batteries for them as well as the Phoenix. The Tucson also needed a new ignition switch and new plug wires as varmints had apparently found the prior ones quite tasty. The Red River is running great. The brake canisters on the Tucson had all taken “a set” and were leaking badly. Rebuilding vacuum canisters isn’t rocket science, but it does take patience and sound planning and preparation. It takes about 35 minutes to remove each canister, rebuild and replace. The eight on the locomotive and one on the tender have been completed. We will finish the remaining seven on the tender in May. The motor sounds great running in neutral. In May, we will focus on the same activities on G16 no. 582 as she and the Coconino will get a new battery and the Coconino will get a magneto.

|

|

Amanda continued her work at the A & P this month by washing the Phoenix tender and polishing its brass. She is planning to wash the Mackey tank car and the ditcher. She is going to paint the lettering on our logo plates mounted on both sides of our turntable in May. I’m excited to get those logo plates back up there.

We started readying one of our engine display racks in the engine house for the return of our pre-war Addison G12 early next month. I’m really excited to get that locomotive back here.

|

We received the Ubolts and plates that I ordered for the spring pad assemblies of our E10 coach trucks. We completed assembly of two of the three coach trucks and just await the truck arches to get back from powder coat and need to add the wheels. We still have some cosmetic work and the wiring to complete on the two drive trucks and the wiring on the power pick up rear observation car truck.

|

|

Dave and I finally got the eight turnbuckles on the turntable sanded and painted.

|

We continue our work on the red topped picnic tables.

Happy and safe railroading everybody!

04/22/23

The college student daughter of one of my work colleagues was on spring break one week this month and worked four days of that week on the A & P. Amanda cleaned and dusted the engine house, polished the brass on the Sandusky and Phoenix, washed and detailed the Tucson and washed and detailed the Coconino. She also got started polishing the brass of the Red River. She did a great job and they all look amazing. She will work additional hours at the Arizona and Pacific as time permits the rest of the school year.

|

|

|

|

|

I had originally planned to have separate canvas curtains made to protect each side of the G12 Carvana structure as well as the G12 truck rack and the E10 rail rack. I had a change of plans and purchased a 10 x 30 foot billboard vinyl tarp. It covers and protects all three racks for weather, dirt and leaves that collect moisture. It isn’t quite as stylish, but is a lot less expensive and is practical. The thick vinyl has held up very well in other backyard applications here.

|

We worked several late nights this month on the conversion of the Sandusky from lead acid batteries to Lithium Ion ones. For a number of reasons not related to the Sandusky, we hadn’t had her on the tracks past the turntable in over three years. When I attempted to charge the batteries last week, not unexpectedly I found the batteries were shorted and dead. It took eight of the 6 volt lead acid batteries to complete our 48 volt system. Instead of replacing the eight batteries with new lead acid ones, I decided to utilize state of the art Tesla style Lithium Ion ones.

|

We vacillated between going with three or four of the Lithium Ion batteries. Each battery is 48 volts and with four we have 120 amp/hours. Dan Tack of Precision Railroad Products in Phoenix designed the electrical retrofit, sourced the components and completed the electrical installation. We had the electrical portion of the work completed in time for rides on the 18th and 19th, but we still needed to modify the battery tray for the new batteries which are much smaller than the original ones and add the charging port and a number of gauges. The system has a slick onboard charger, digital voltage read out on each battery and the ability to turn off individual batteries if the train will be out of use for an extended period of time. Another nice feature is the 10 year (non-prorated) warranty versus the three year pro-rated warranty of the lead acid batteries. The individual battery cost was about 4 times the lead acid cost, but I only need four batteries instead of eight and the warranty is 3+ times as long. I’m excited to see how they work out long term.

|

We made the modifications to the battery tray, installed the charging port, added a multi-display gauge (volts and amps) and made a few changes to the protective battery box to secure and protect the batteries the following weekend.

Big note to self: do not commit to give rides unless you are certain that you have equipment ready to run. We will be starting on each of our gasoline powered locomotives next month as each needs the old fuel drained, carburetors rebuilt, new fuel pumps and new batteries.

We had 6 passengers on 3-18 and 7 more on 3-19. We made about 30 laps.

|

|

|

We installed our re-chromed MTC emblem on the nose of locomotive 26 this month and I think it looks great on there.

|

The bearing retaining plates for our E10 coach trucks made their way back from the powder coater. I pressed in the seals and they are installed. The bearings have been pressed onto the axles and the axle assemblies have been completed. I ordered new ubolts for the E10 spring pad assemblies as the original ones were badly pitted and bent. The replacement ubolts will arrive in April and then we can get those trucks completed except for the wheels that are delayed at the machine shop. The wheel hubs and tires are both still delayed and it may be May or June before we have them here. Some of our E10 coach axle castings are very early TD-1 castings which is cool. Note the change to the final production casting with the change in location of the oil drain hole.

|

Our four new picnic tables have been completed except I am going to fabricate some steel corners to protect the seats from my puppy.

We replaced a table top board in one of our red tables and have some bolt replacement and repainting to be completed on two red tables that are in the other end of the yard from the new green ones. I ordered and we have the bolts and washers on site. They will all be in good shape by October.

|

Our G12 brake shoes are delayed at yet another vendor as is the next batch of G12 truck arches.

Dave cut out the seat bottoms for 17 additional E10 seat cushions. There are 4 different shapes; the end of car seats, the very early center car seats which had an uncomfortable straight across back, the later center seats which were ergonomically curved and the expanded engineer seats. As my neighbor gets the time, he will upholster them for us.

|

We still have an additional E10 coach and observation car that will need seats when they restored in the future; we will have those eight seats upholstered late this year or early next

I am having talks with a second body shop about painting our two G12 trains. Our pre-war Addison G12 locomotive and observation car will be the first two projects going to the new shop.

Happy and safe railroading everybody!

03/28/23

Our recent E10 acquisition in Indiana was originally scheduled to arrive here on January 31, but bad weather conditions in the Midwest delayed its pick up and pushed its arrival into early February. My recent experiences with trucking companies have been very disappointing with items being lost, badly damaged or delivery surcharges tripling the shipping costs. Hats off to ABF Trucking, they – got our train here, didn’t lose or damage anything, did it for the agreed upon price, had a delivery appointment and even arrived an hour early… They couldn’t have been more professional and courteous.

|

|

|

Our new E10 is no. 45. We acquired her in an auction a few miles from Rensselaer. The key acquisition in the lot is a rare E10 baggage car. I shared last month that I have only seen 2 and while I suspect a few more than that were built, I believe the number is less than 6. We also acquired a late style coach and an observation car in this transaction. They are bodies only. The observation car is missing its top casting and the locomotive is missing its two hoods and driveline cover. We can have the hoods and cover fabricated, but the top casting for the ob car is a tough find. We will also need to replace the front skirt of the locomotive. We are one drive truck short of having all of the trucks needed for these new acquisitions. If anyone knows of any E10 trucks, truck parts or wheels lying around anywhere, please contact me. I was able to locate a set of cab faux horns for no. 45 locomotive and also found a motor pan that is in very nice shape.

|

|

|

|

|

|

Dave and I completed the installation process of the first twenty G12 truck arches back from powder coating. We removed the leaf spring on one side of the trucks and added both arches and replaced the leaf spring. We added the U clamps and alignment bolts and added the wheels. We still have about 10 more G12 trucks to reassemble, but those twenty arches are still backlogged in machining. Once received, they will head to powder coating.

|

Our rack for G12 trucks has been powder coated and assembled. It will have canvas curtains on the east and west sides to protect the trucks once my neighbor has the time to cut and fit them. It will store and protect 30 G12 trucks at a time.

|

|

Our four new picnic tables have been completed. The tops are painted green and the seats are painted grey. Prior to final assembly, the seats were shortened by a couple of inches at both ends to make ingress and egress easier. We have repaired and mounted the 4 Sunbrella umbrellas from the 1950s.

|

We have some bolt replacement and repainting to be completed on two of our three red tables that are in the other end of the yard and a board to replace in the third red table. They will all be in good shape by operating season in October.

Our four MTC breast badges just arrived back from cleaning, polishing, de-chroming, re-chroming and re-polishing. They are brass that is chrome plated. They came out great, really great and look close to brand new. One goes on our red and white post-war E10, one goes on our post-war G12 and the other two go on other post-war projects. They really dress up the front end of the locomotives.

|

|

As the result of the extremely wet winter and our busy schedules, our E10 track is still in California. Realistically, it looks like April before it all gets over here.

Dave and I cut and fit several more handles for our train no. 20. It isn’t rocket science, but it is time consuming. Unlike the post-war G12s, there doesn’t seem to be a standardized template and the mounting holes vary in placement from car to car and side to side. The handles themselves vary in length randomly.

Derek Bennett, who is currently doing a beautiful job restoring MTC G16 train no. 580 (4) stopped by the A & P and we discussed plank bearings, MTC trucks and park trains in general. He is also an active member at the American Heritage Railroad in Greenville, IL near St. Louis. If things work out right, we may be able to visit the American Heritage Railroad and see their operation this summer. We first rode on its equipment back in 2007 when we attended the convention at the ATT & NW Railroad of John Woods in Steelville, MO.

|

We continue to work on our five California E10 trucks. All of the trucks have been completely disassembled and degreased. The two 2 power trucks have been rebuilt with new brass gears, seals and bearings. They await new hardware, painting, power truck arches, side frames, safety bars and wheels.

The coach trucks are all back from powder coating and if time permits, we’ll get the bearings pressed onto the axles and get the coach trucks reassembled in March. The wheel hubs and tires are still delayed and our powder coater is starting to get so busy that what was taking a week to get back is now taking three to four weeks. Coordinating when all the parts will be here and planning work sessions is getting increasingly difficult. Our 10 E10 wheel hubs and tires we ordered from our local machine shop are now on scheduled for delivery in late March or early April.

Our G12 brake shoes are delayed at yet another vendor.

Happy and safe railroading everybody!

02/28/23

We were lucky enough acquire another E10 locomotive variant body style this month and she is currently on her way out here. I will provide more information and photos once she arrives. She is no. 45. We also were lucky enough to acquire a rare E10 baggage car. I have only seen 2 and while I suspect a few more than that were built, I believe the number is less than 6. There are 4 passenger seats in the baggage car just like the coaches which also have 4 seats, but the seat back of the baggage car inner seats is straight across rather than curved like the coaches and likely not very comfortable. We also acquired a late style coach and an observation car in this transaction. They are bodies only. The observation car is missing its top casting and the locomotive is missing its two hoods. We can have the hoods fabricated, but the cast top for the ob car is a tougher find. I have a couple extras for G12 Ob cars, but of course they are a different size. We are one drive truck short of having all of the trucks needed for this new acquisition. If anyone knows of any E10 trucks, truck parts or wheels lying around anywhere, please call me.

Pat McCarthy an E10 owner from Pleasant Hills, MO and the Superintendent of the beautiful Big Spring & Southern Railroad (7.5 inch) was in town visiting family for a few days at the end of the year and stopped by the A & P to visit. We had the opportunity to discuss all things MTC as well as his awesome 7.5 inch projects. I also enjoyed visiting with his wife Ann and Hal the family rail dog. I am hoping to visit his railroad during his June meet this summer.

|

|

Peter Bryan from Taylor, Texas and a member of Maricopa Live Steamers was in town for the January meet and stopped by the A & P to check things out. We had a nice visit.

We continue to work on our 5 recently acquired from California E10 trucks. Two are power trucks, one is power pick up only and two are standard E10 trucks. All trucks have been completely disassembled and degreased. The 2 power trucks have been rebuilt with new brass gears, seals and bearings. We fabricated a spring pad assembly to replace one cobbled together in someone’s garage, rebuilt six leaf spring assemblies, built 4 safety bar assemblies for coach trucks and built four safety bar assemblies for power trucks to replace damaged ones. About half of the safety bars, spring pad assemblies, leaf springs, truck arches and axle housings are back from powder coating. The other half won’t be ready until mid-February.

|

I ordered 10 E10 wheel hubs and tires from our local machine shop and was originally told early February for delivery. They have been down two guys so now I am looking at mid-March.

I designed, and Jerry Graves improved, a rack to store 30 rebuilt G12 trucks that I will soon have completely refurbished and for sale. It is currently at powder coat, but should be ready for pick up early in February.

We finished the rough body work and assembly of our Addison G12 locomotive and she along with her matching observation car are ready to head to body and paint as soon as he has room in his shop.

We finished our plank replacement work last month and my jack hammer work was completed a couple of months ago. We have had day after day of rain the last six weeks; I finally had a couple of dry days in a row and I commissioned a dump trailer that I filled with the piles of old wood planking and concrete chunks from Rock Creek. The concrete chunks were wheel barrowed to the trailer and I used our flatcar and loaded the planking on it to move that material to a few feet from the trailer. It’s nice to have that stuff out of here!

|

|

|

We mounted the decorative horns and handrails on locomotive no. 26. We still need to install the instrument panel and driveline cover, assemble the hood latch assembly and install the hood. We also have a bit of paint touch up work and assembly to complete on the locomotive and observation car before we start on the wiring of the locomotive and observation car, but progress is being made. We did got the drum head mounted and drilled and rtpped the observation car top casting.

The two coaches from our no. 20 train returned from body and paint. They are orange and burgundy and look pretty good. The holes for the handles were there, but the handles themselves were gone before we acquired these cars. Dave and I cut and fit polished stainless steel rod and replaced the handles. We also added the upholstered seats which had been completed several months ago. There are three more cars to this train that we hope to get into and out of body and paint this fall.

|

|

|

|

Dave and I started the installation process on the first twenty G12 truck arches back from powder coating. We removed the leaf spring on one side of the trucks and added both arches and replaced the leaf spring. We still need to add the U clamps and alignment bolt before we can mount the wheels. We still have sixty more arches either being machined or in powder coating that will return here in the next several weeks.

|

Our recent E10 acquisition in Indiana was originally scheduled to arrive here on January 31, but bad weather conditions pushed its arrival back into early February. I hope everything arrives in good shape. My recent experiences with trucking companies have been very disappointing so I have my fingers crossed.

Happy and safe railroading everybody!

01/14/23

We received locomotive 26 and its observation car back from paint and body the week before Christmas and they look outstanding. We still have plenty to do adding bolt on trim pieces windows and wiring. Two coaches from E10 train no. 20 are also ready to return from body and paint, but delivery challenges has pushed their return to mid-January. The locomotive from that train and observation car no. 20 will go to body and paint in January 2023 and we hope to have them back in April. We also hope to have our post-war G12 into and back from body and paint in 2023.

|

|

|

|

|

Our pre-war G12 and two cars of our newest E10 are 2024 projects and 2025 will conclude our E10 and G12 body and paint projects. Additional body and paint projects include our G16 AB, a S16 locomotive only and a S16 locomotive and tender to complete in the balance of 2025 and 2026. I am looking for a second shop that would complete the body work on our G16 and S16 projects while the current shop continues work on the E10 and G12 projects. It looks like I will be in corporate America 4 or 5 more years to have all these projects paid for before I retire.

Our recently acquired California E10 power trucks have been rebuilt mechanically. We removed all of the sheared off bolts in the castings. We rebuilt the mechanicals with new bronze gears, new axle bearings, new drive bearings and new axle and drive seals. We are still in the process of rebuilding the spring pads and safety bar assemblies. Seven of the wheels had much wider tires than the original specs and we turned them down on the lathe to the original specifications. Four of the wheels were in great shape didn’t need any work at all and nine we pressed apart and they will need new tires.

We completed rebuilding four spring sets and have started on rebuilding the spring pad assemblies. We have also gathered the parts for rebuilding several safety bar assemblies over the next few weeks.

I have four of our MTC breast badges out for cleaning, polishing, re-chroming and re-polishing. It will be a few weeks before they are completed and ready for pick up. One goes on our red and white post-war E10, one goes on our post-war G12 and the other two go on other post-war projects. I am optimistic they will meet my quality expectations.

|

All of the wood has finally been cut, fit and mounted in our new picnic tables. The routing work on six boards comprising the tops of two tables still needs completed as does final sanding. The priming and painting work on two of the tables is just barely underway. The final work on the picnic tables has been delayed by our very wet winter out here. I had hoped to finish them over the holidays, but it was too wet to make that happen.

|

|

We completed the last of the plank work on trestle 5 and will start installing the trestle signage soon.

We have 41 truck arches at the powder coater and look forward to their return. Twenty-five more arches will return from the machine shop in January and will head to powder coat shortly thereafter. The last 15 of the castings will go to the machine shop in March. Once these 41 arches are on site, we can start final assembly of that number of G12 trucks. That entails adding the truck arch, mounting the second of two leaf springs and adding the four wheels. I am looking forward to seeing all of the G12 trucks completely assembled.

We made more progress on our Addison locomotive this month and she is almost ready for the skills of professional body and paint men to finish her sheet metal restoration. I am really excited to see how she is going to look once the professional body men get their hands on her. That raked and narrow pointed nose makes her look like she is racing down the track even when she is sitting still!

|